bourvil

Member

Hello all!

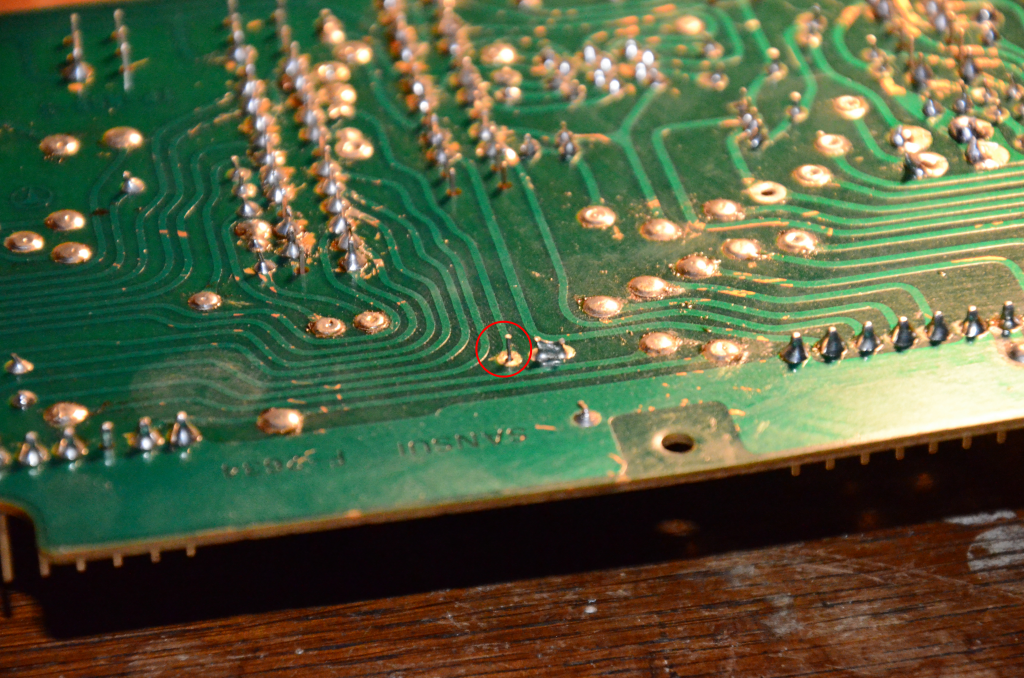

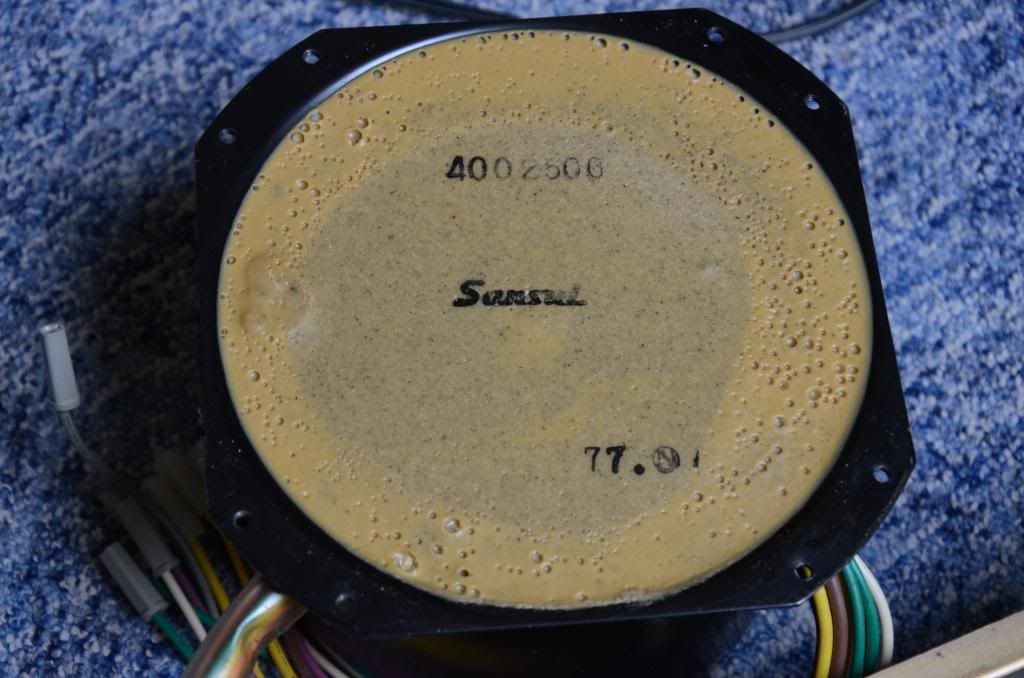

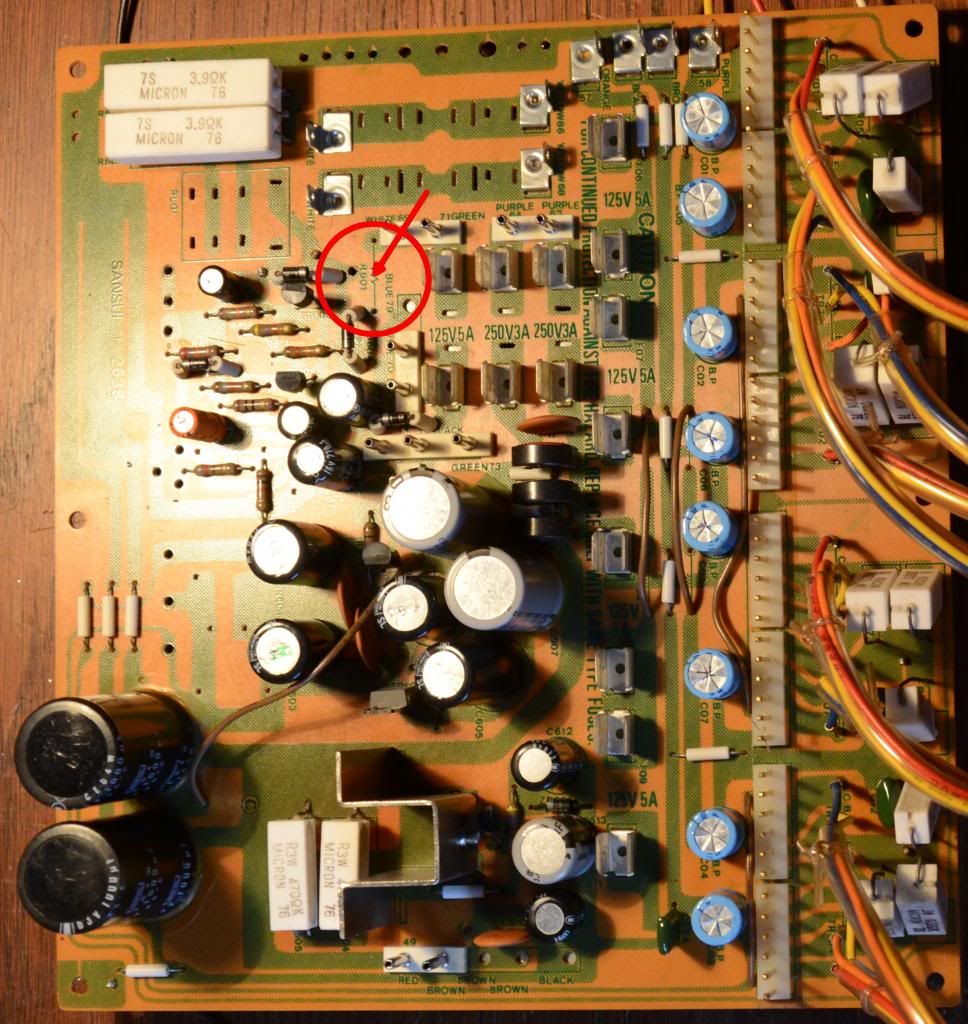

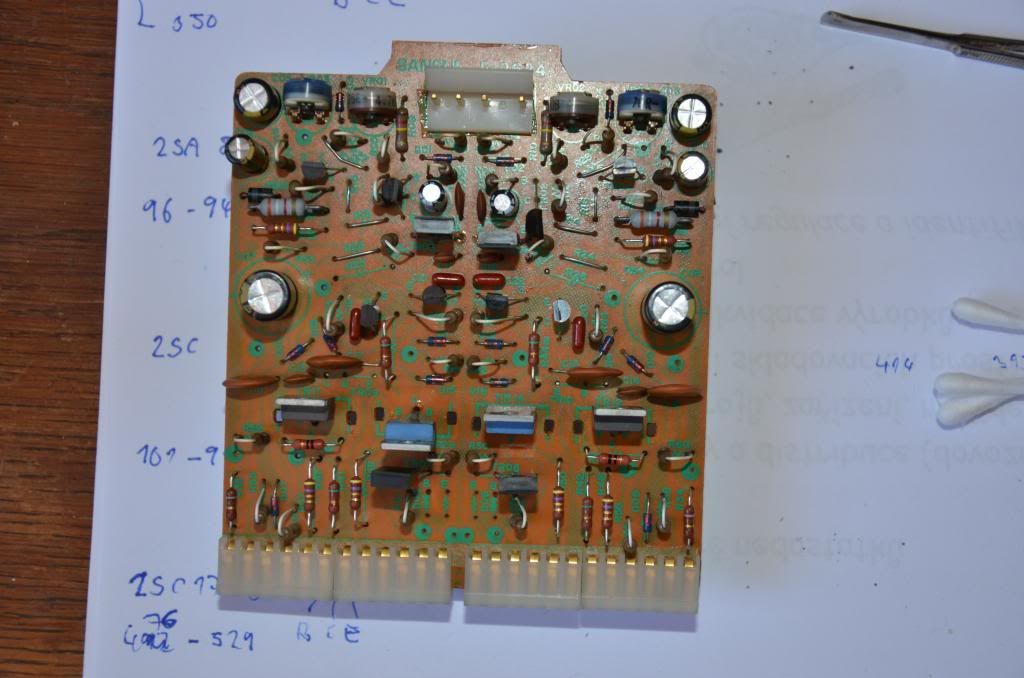

As I must be really addicted to Sansui I could not resist to get this beast in nice condition but with typical problems including drifted values of fusistors, no signal on several modes and muffled sound with tendency to disappear on one or both channels overall.

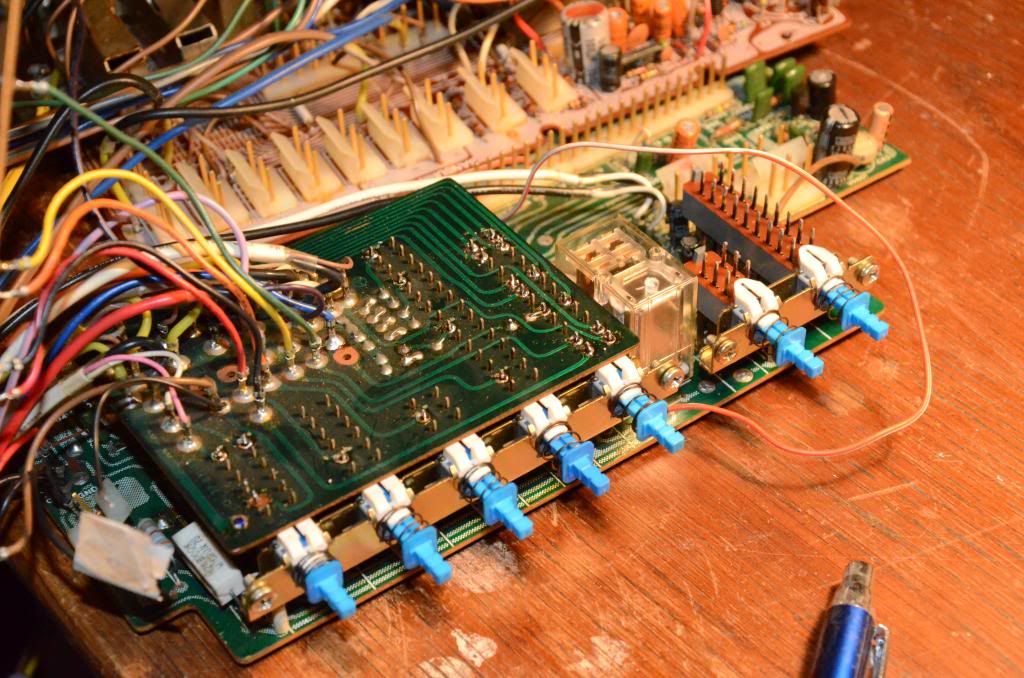

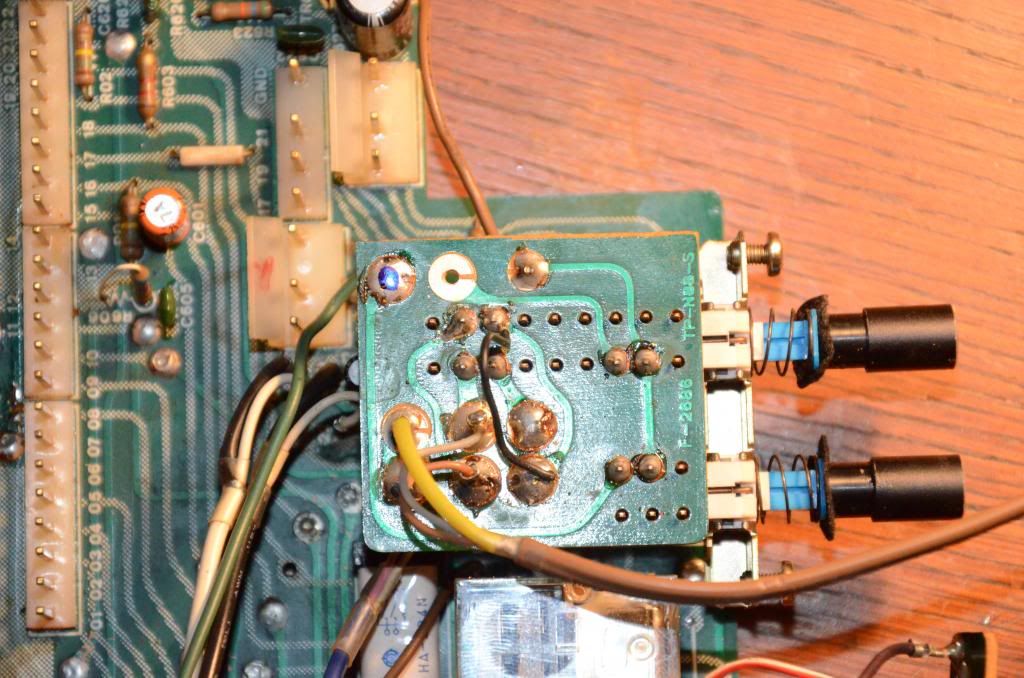

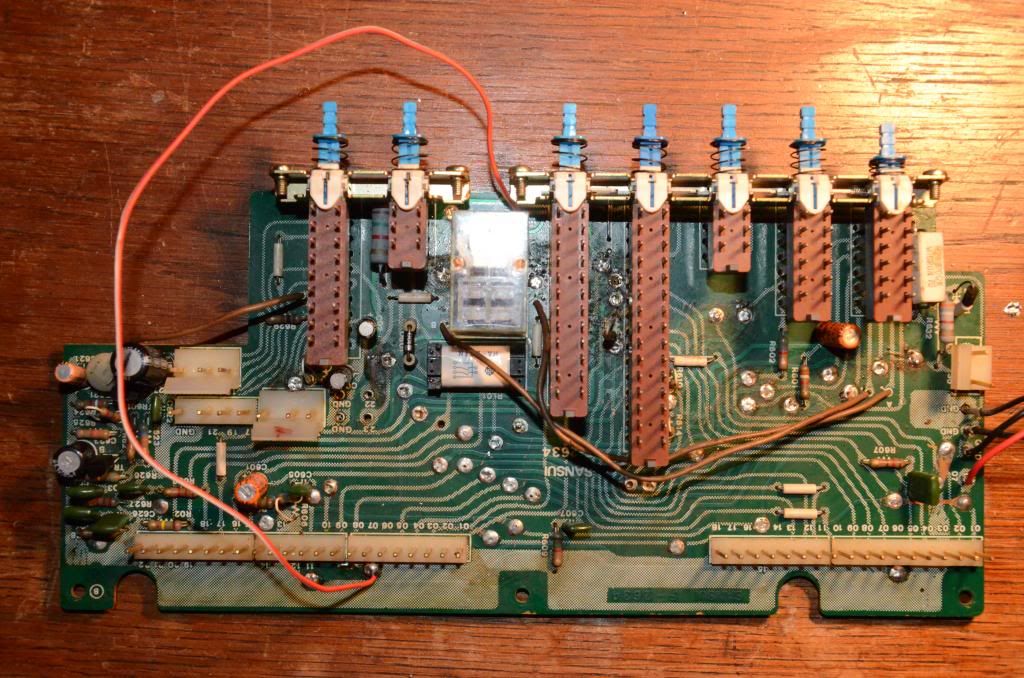

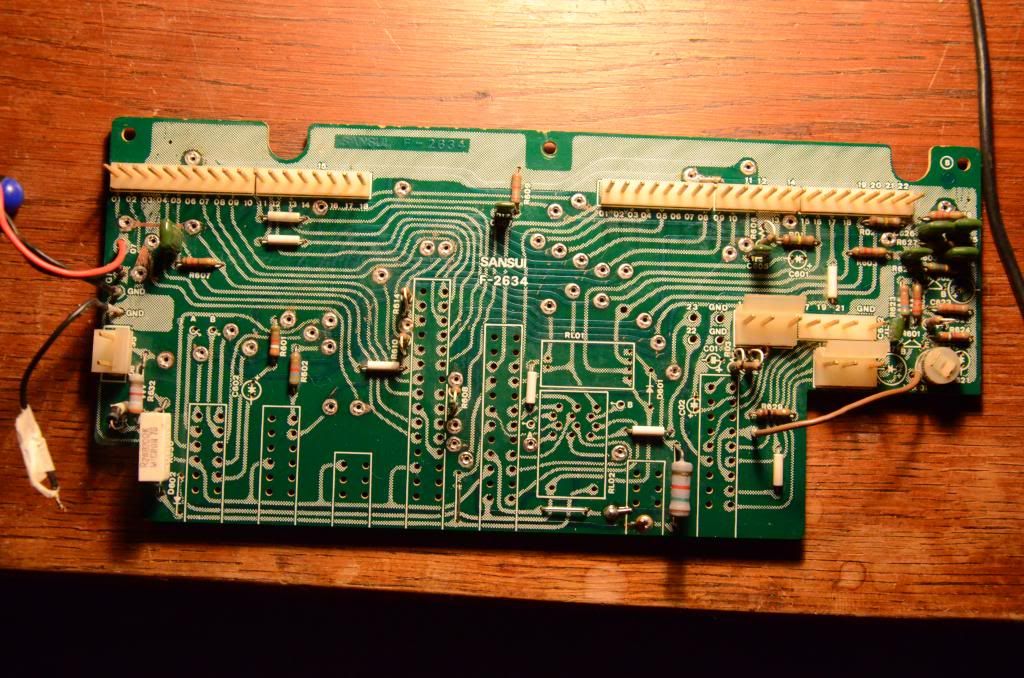

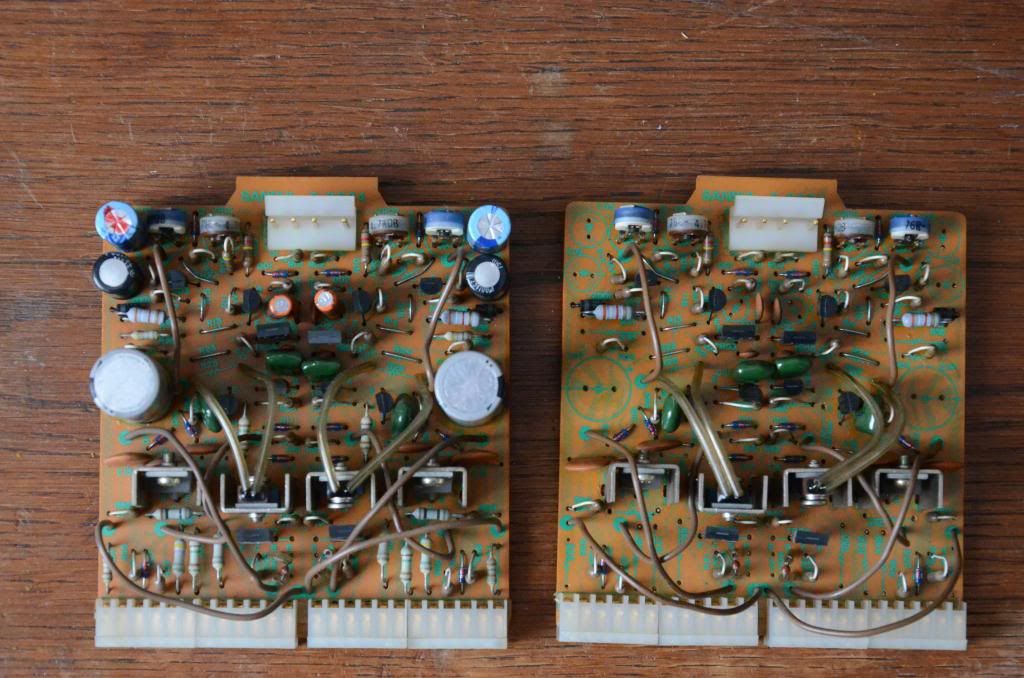

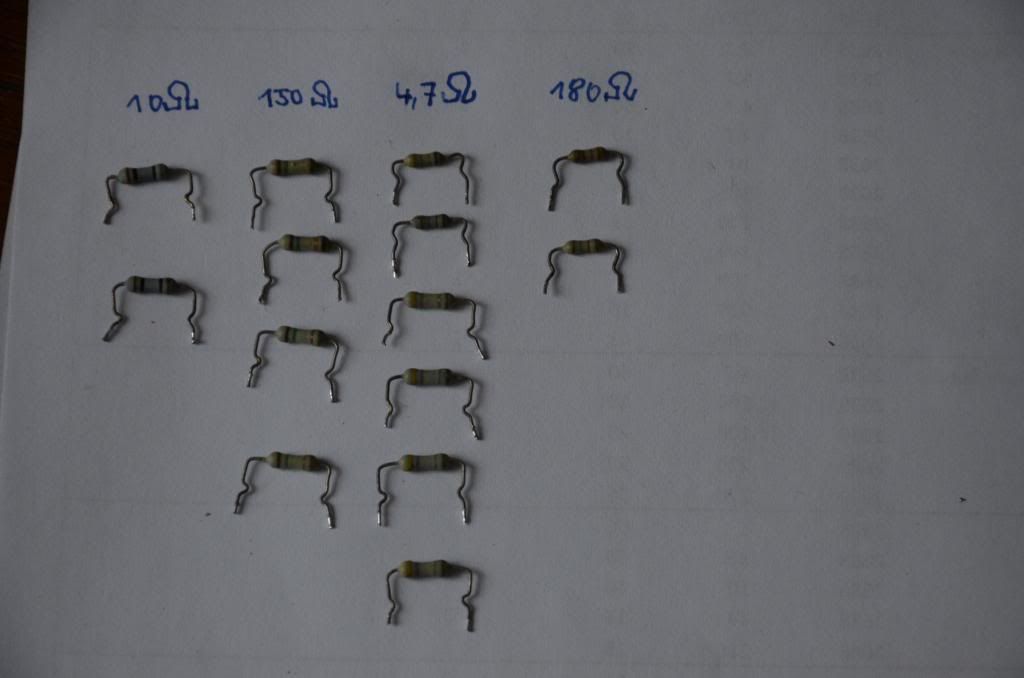

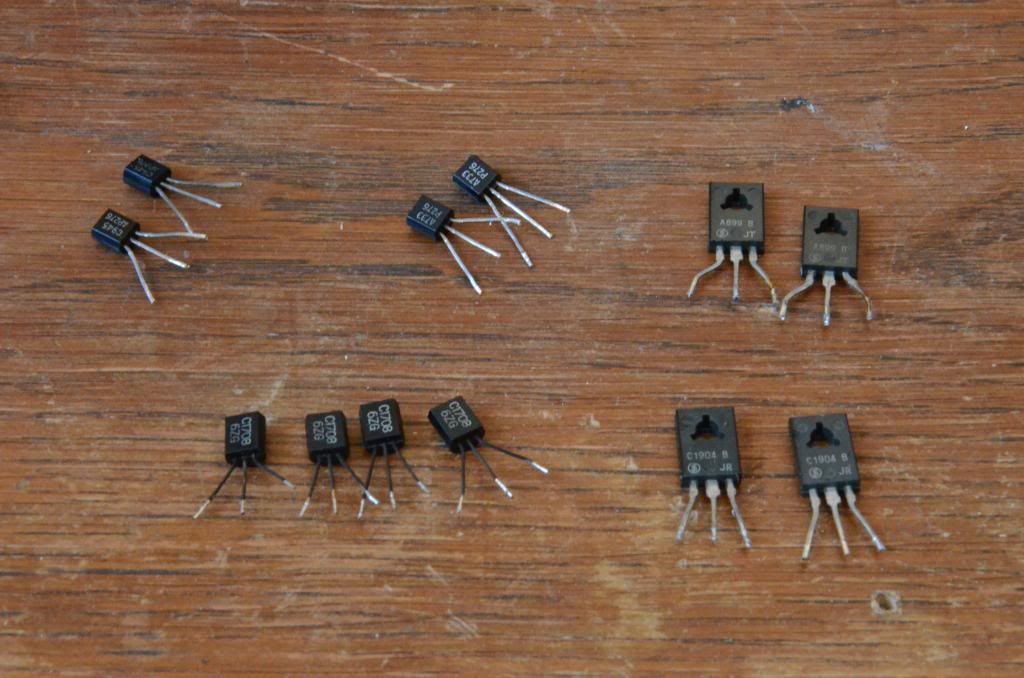

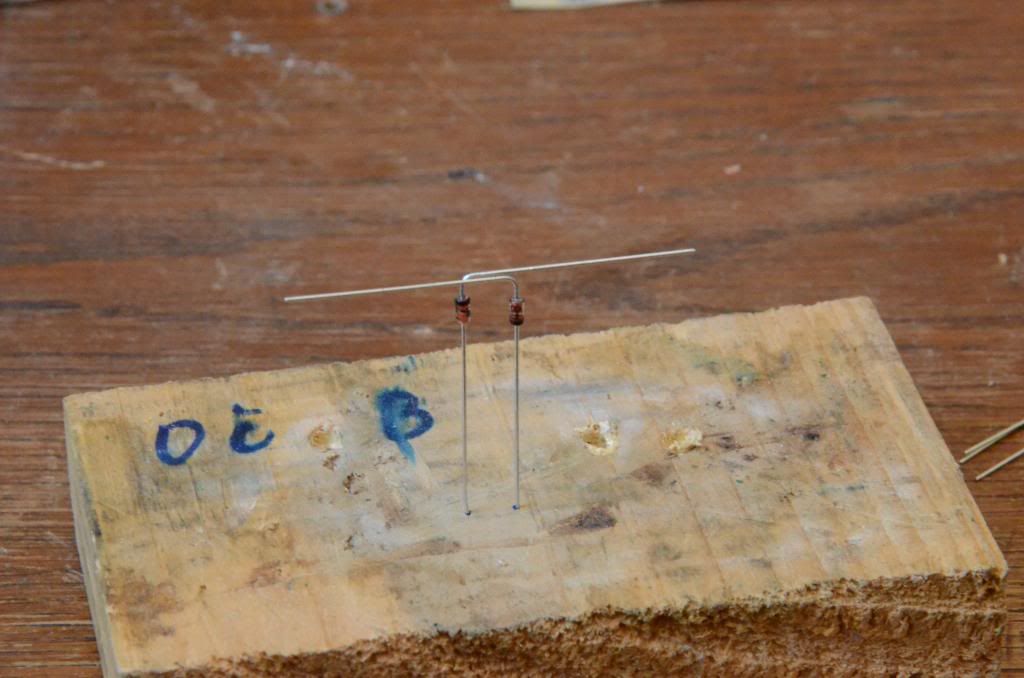

I plan to do full restoration including recap, replacing fusibles and all other components out of specs or those proven to be faulty (VD1212 etc.)

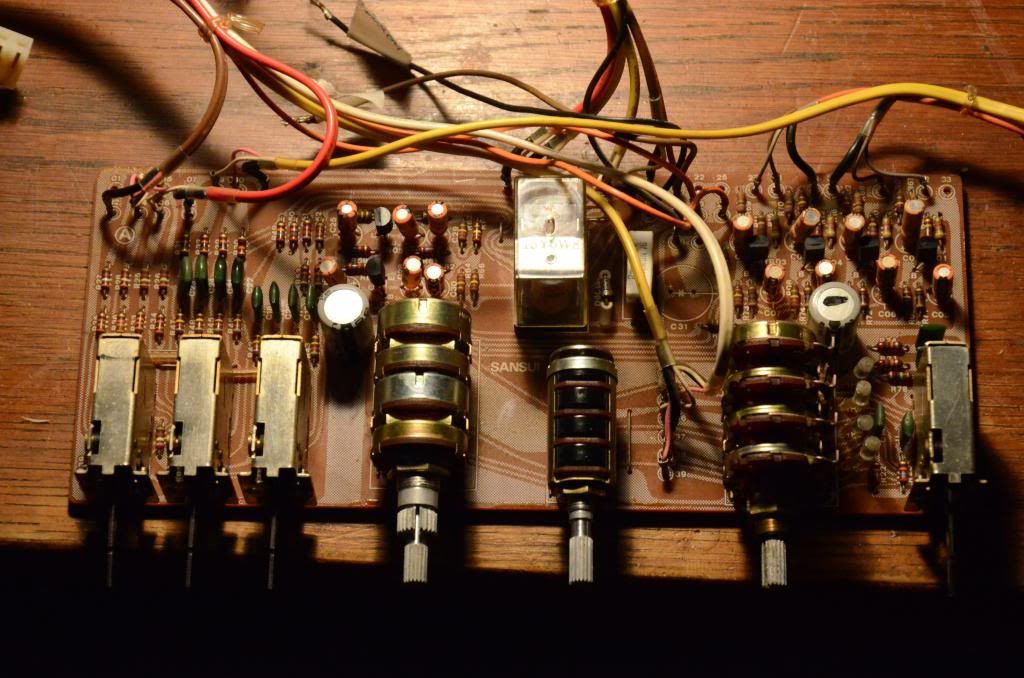

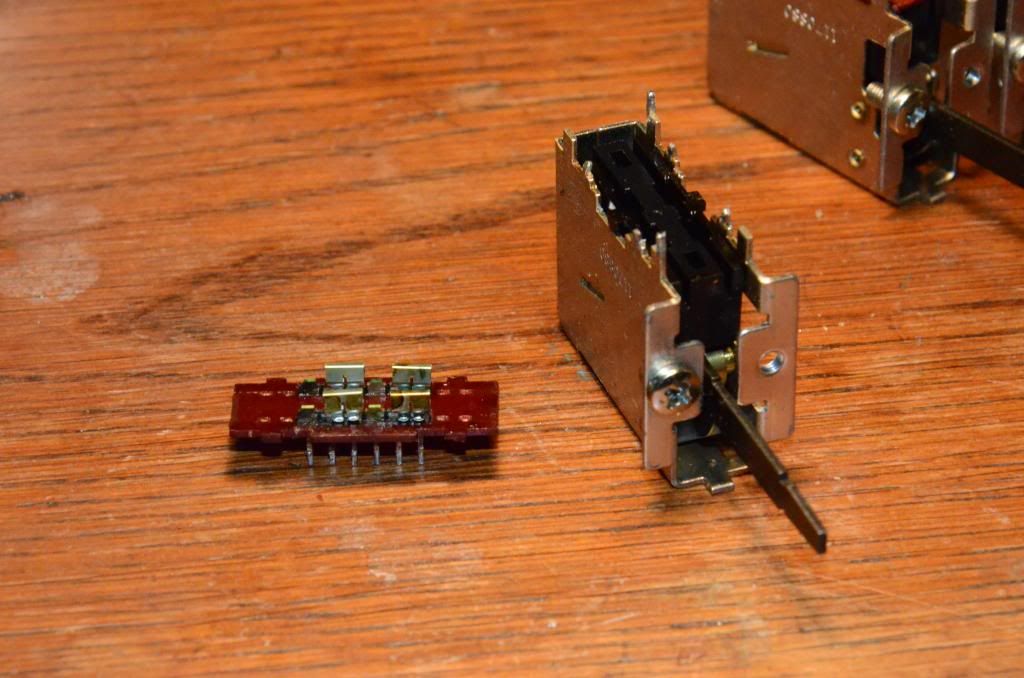

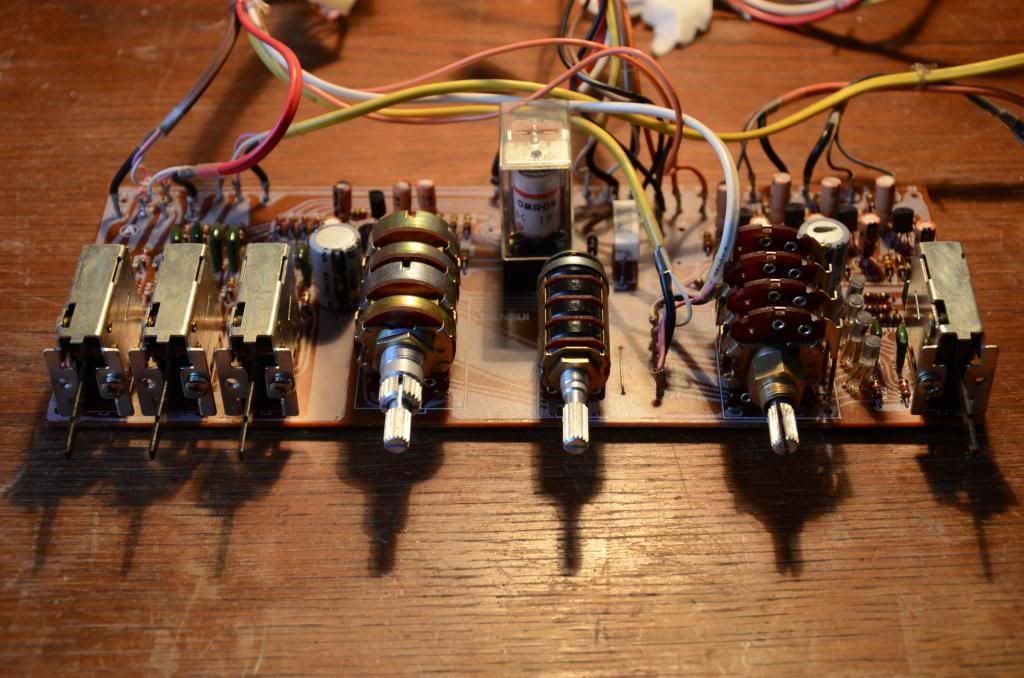

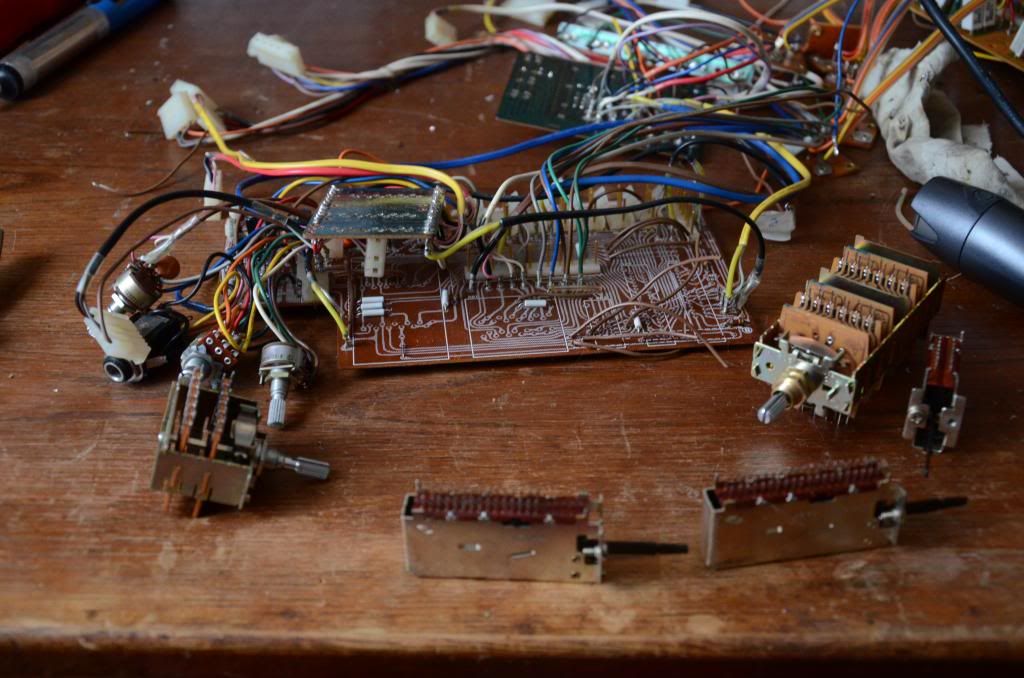

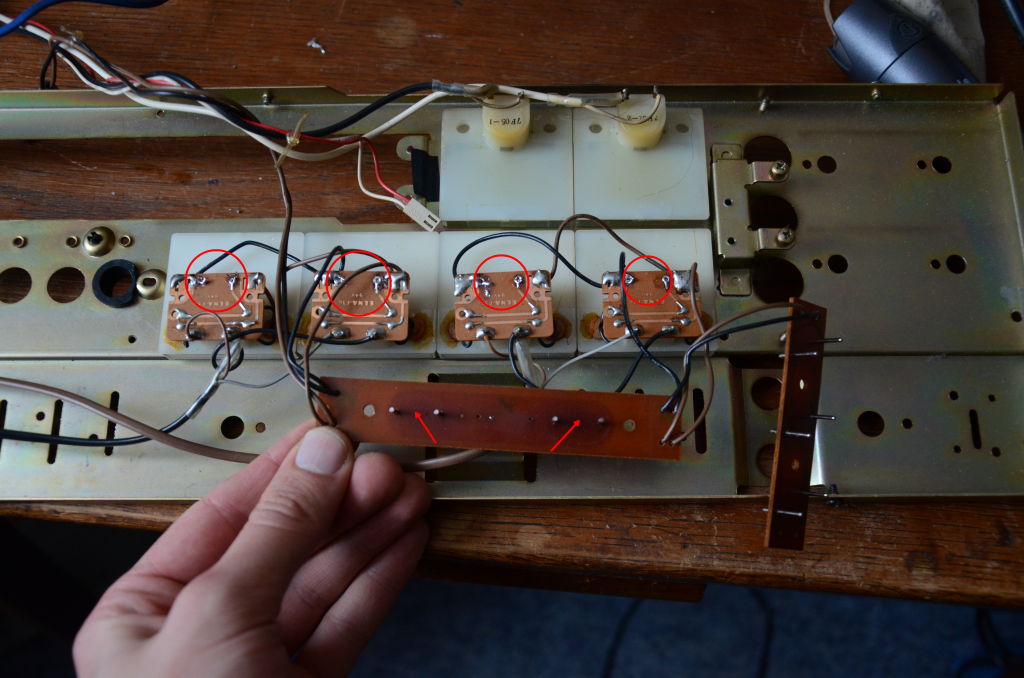

I also plan to clean all unit inside and outside including disassembling and cleaning of switches, pots and relays.

As guru of restoration Kale I would like to share experience (and photos of course) with all of you during this challenging restoration.

Finally I must say big thanks to Trnsfmr for his invaluable QRXrestore web and many others who regularly contributes to this great site.:tresbon:

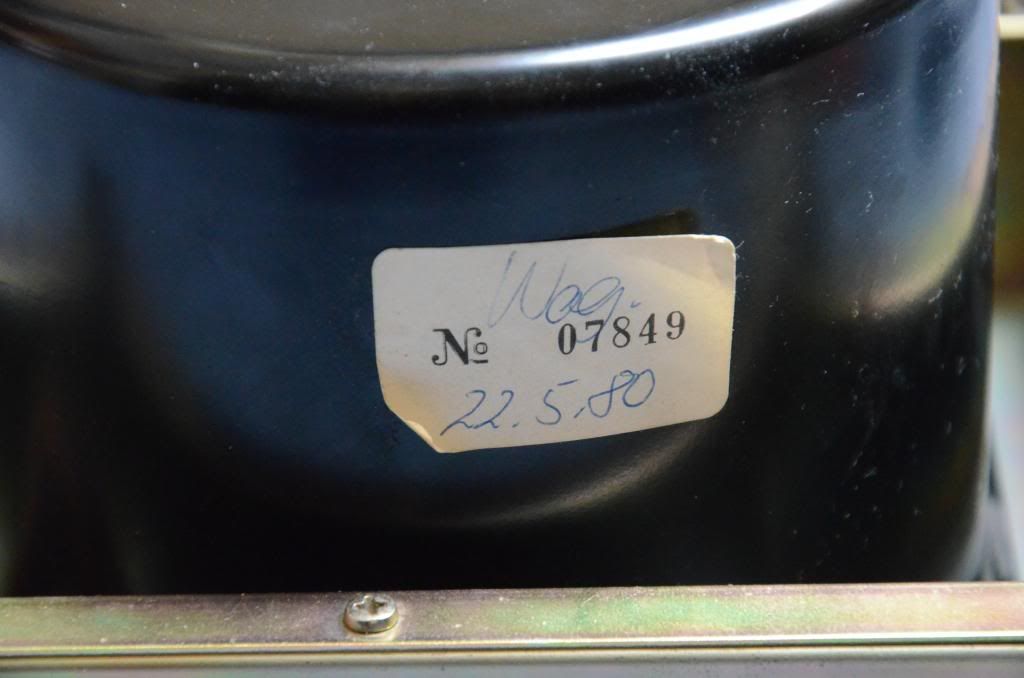

So for now, how it all started: SOme days ago I got this small pckage into my music den. it was HUGE and heavy as anvil.

It took some time to get the treasure from very well packed box and this was the result:

I set it temporarilly on the place in my system to examine how the unit works and where are the problems. Almost all lights are working and as the place arround the bulbs is only light "smoked" it seems that this unit has low running hours what is great . Although, majority of switches must be dirty as only source I got relatively clean was dolbyized radio. All other sources were muffled and after some time one or both channels came out which was crowned with loud click from speakers when I turned the unit off.

. Although, majority of switches must be dirty as only source I got relatively clean was dolbyized radio. All other sources were muffled and after some time one or both channels came out which was crowned with loud click from speakers when I turned the unit off.

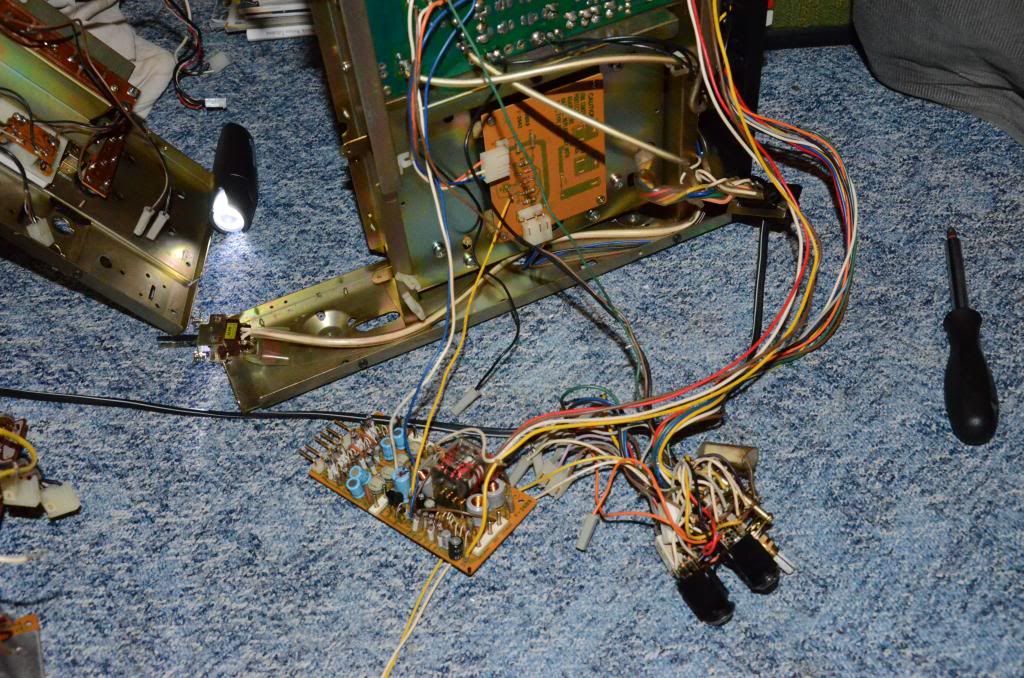

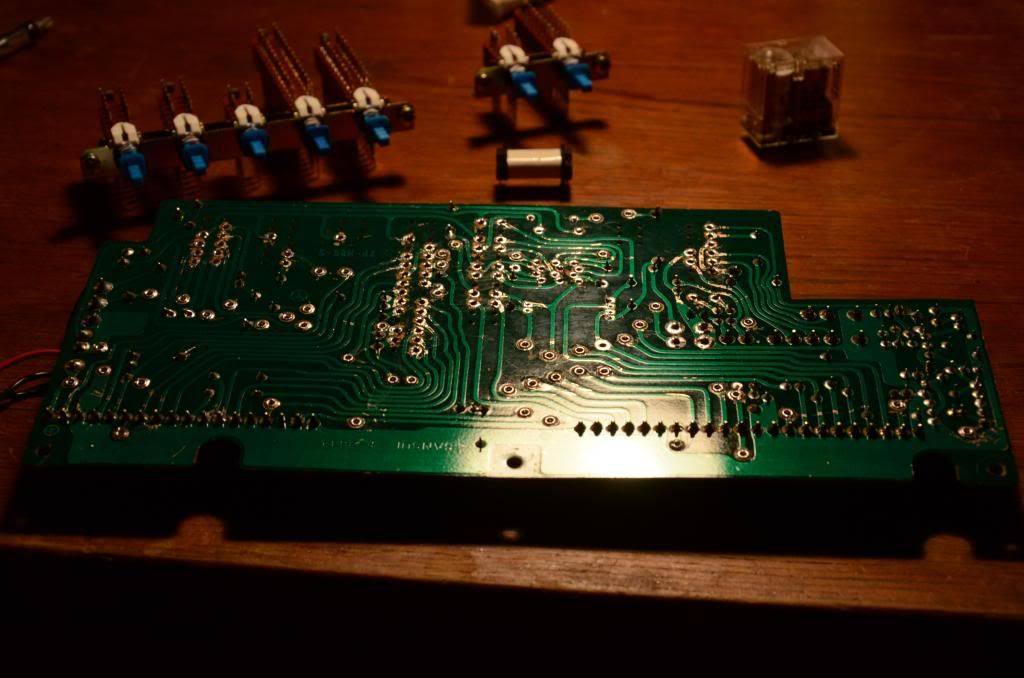

Next step is to open the unit and examine the condition of internals so stay tuned!

As I must be really addicted to Sansui I could not resist to get this beast in nice condition but with typical problems including drifted values of fusistors, no signal on several modes and muffled sound with tendency to disappear on one or both channels overall.

I plan to do full restoration including recap, replacing fusibles and all other components out of specs or those proven to be faulty (VD1212 etc.)

I also plan to clean all unit inside and outside including disassembling and cleaning of switches, pots and relays.

As guru of restoration Kale I would like to share experience (and photos of course) with all of you during this challenging restoration.

Finally I must say big thanks to Trnsfmr for his invaluable QRXrestore web and many others who regularly contributes to this great site.:tresbon:

So for now, how it all started: SOme days ago I got this small pckage into my music den. it was HUGE and heavy as anvil.

It took some time to get the treasure from very well packed box and this was the result:

I set it temporarilly on the place in my system to examine how the unit works and where are the problems. Almost all lights are working and as the place arround the bulbs is only light "smoked" it seems that this unit has low running hours what is great

. Although, majority of switches must be dirty as only source I got relatively clean was dolbyized radio. All other sources were muffled and after some time one or both channels came out which was crowned with loud click from speakers when I turned the unit off.

. Although, majority of switches must be dirty as only source I got relatively clean was dolbyized radio. All other sources were muffled and after some time one or both channels came out which was crowned with loud click from speakers when I turned the unit off.

Next step is to open the unit and examine the condition of internals so stay tuned!