dorr

Active Member

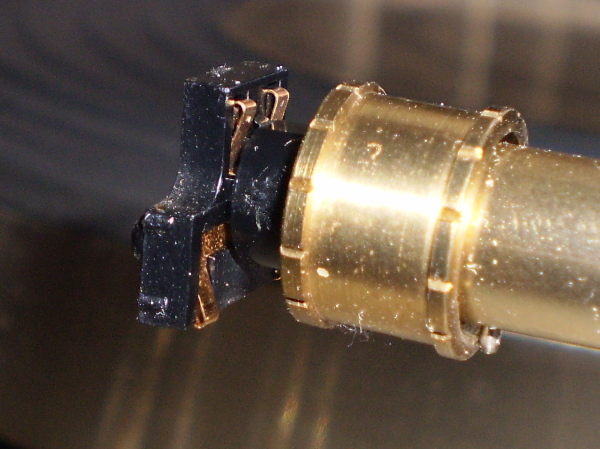

Has anyone seen this before?

Crazy glue may hold the plastic piece back in place. I thought maybe a piece of copper from a circuit board may wedge back in place while trying to glue it or is it impossible to repair.

Any ideas? I got it this way so I do not know how it happened. There may be other damage.

It's also missing the cables to check it out if it is repairable.

Crazy glue may hold the plastic piece back in place. I thought maybe a piece of copper from a circuit board may wedge back in place while trying to glue it or is it impossible to repair.

Any ideas? I got it this way so I do not know how it happened. There may be other damage.

It's also missing the cables to check it out if it is repairable.

Attachments

Last edited: