Plumberboy1

Active Member

http://www.tubes4hifi.com/bob.htm

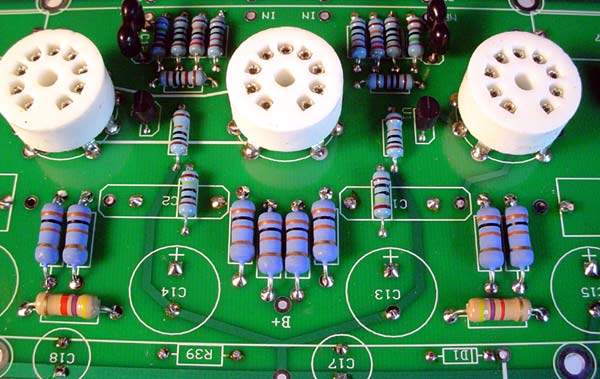

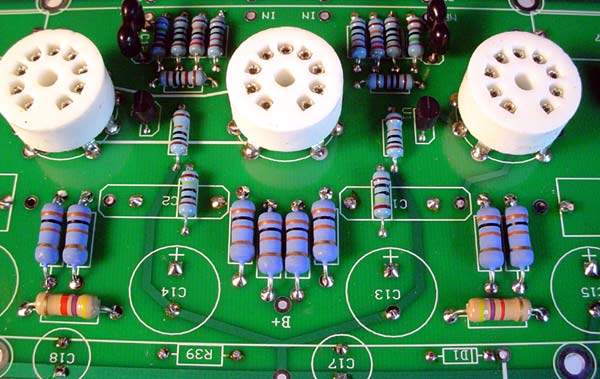

I purchased a ST70 kit with the cap upgrades from Bob. The circuit board is finished.

I purchased a ST70 kit with the cap upgrades from Bob. The circuit board is finished.

Do put an isolation layer around the "russian caps" on the underside of the board.

A cardboard strip under each is enough. Or put each cap in a crimptube before mounting. Just make sure thatA isolation layer? I know how I could do that too. I do resin casting. I make 1:24/1:25 Scale model car parts. I could create a dam around these Russian caps. I would mix and pour a small amount of silicone in the damn and then it would cure. I would be using a platinum silicone. The Mold Star 30. Anybody think this is not a good idea? Otherwise, I am uncertain how to isolate them.

https://www.reynoldsam.com/

https://www.reynoldsam.com/product/mold-star/

http://smcbofphx.proboards.com/board/45/resin-casting Here is some of my model car parts making. Silicone and resin is an amazing world!

Take your time, double check your work periodically and FOLLOW the instructions!!!!

Get a magnifying glass and check the solder joints on that board. Those solder pads are small and can easily cause a problem if not done correctly.

I built that amp a few years ago and I'm still VERY impressed with it. Get the GL KT-88 output tubes and a EH 12BH7 center and 2 TungSol 12AU7 outer tubes and it's party time!!!

Keep posting the pictures

Finished? Not so fast ...

One nice feature of the VTA boards is that the solder pads are double sided. Lot better strength and longevity if you solder both sides. Pay close attention to the tube sockets as those can take a pretty good pounding over time, especially if you're a tube roller. I also give each leg a slight twist after setting the socket into the board to get as tight a connection as possible before soldering.

Also, the PIOs look a bit tight to the board. One potential problem with the metal cases is they can short to a hot circuit. Make sure any component leads near the cases are trimmed short, and maybe add a strip of electrical tape between the caps and board, and you should be fine.

Also make sure you trim any component leads around the edges of the board, and double check clearance when you install it in the chassis. Not uncommon for shorts to happen there also. Worth remembering that even if there's no hard contact, voltage can arc under load.

And ... mostly just pay attention to the directions. Bob & Co have an outstanding step by step guide. I check the items off one by one, and highlight all the "solder later" steps I see. Once the kit is done, I go thru the list one more time, checking each item again for insurance. DO follow the first start instructions as well. And have fun!

No just the foil side. Just Check those solder joints under magnification. They are small and easy to miss or get a cold solder joint on.SO....I should solder on both sides?

Take your time, double check your work periodically and FOLLOW the instructions!!!!

Get a magnifying glass and check the solder joints on that board. Those solder pads are small and can easily cause a problem if not done correctly.

I built that amp a few years ago and I'm still VERY impressed with it. Get the GL KT-88 output tubes and a EH 12BH7 center and 2 TungSol 12AU7 outer tubes and it's party time!!!

Keep posting the pictures

A VERY reliable source of tubes, and a heck of an honest and knowledgeable guy is Jim McShane. http://www.mcshanedesign.net/tubes.htmI already have a brand new set of EL34's and I purchased 3 matching 12AU7 tubes. I did follow your advice. I purchased a quad set factory matched and supposedly a 24 hour burn in for $130.00 and free postage from a Ohio seller on Ebay.

https://www.ebay.com/itm/QUAD-Electro-Harmonix-Factory-Matched-KT88-KT88EH-Vacuum-Tubes-24hr-Burn-in/312031375230?ssPageName=STRK:MEBIDX:IT&_trksid=p2057872.m2749.l2649

Hopefully it was a good deal. I viewed some listings that wanted more than this for one tube. Can't go wrong with a EH tube.

https://www.ebay.com/itm/1x-NEW-Electro-Harmonix-12BH7-EH-Gold-12BH7EH-12BH7A-Vacuum-Tube-GOLD-TESTED/290637902632?ssPageName=STRK:MEBIDX:IT&_trksid=p2057872.m2749.l2649

Also purchased one of these.

Nice work. I have a vintage ST70 that was rough and pitted badly. Cleaned up the chassis and painted a copper color similar to your trannies. Nice vintage color. Its just a stock type board from Dynakitparts with adaptors for the 7199s. Like to hear one like yours. This one looked like it was in a damp basement for decades. She sings again in hammer tone copper.

Nice work. I have a vintage ST70 that was rough and pitted badly. Cleaned up the chassis and painted a copper color similar to your trannies. Nice vintage color. Its just a stock type board from Dynakitparts with adaptors for the 7199s. Like to hear one like yours. This one looked like it was in a damp basement for decades. She sings again in hammer tone copper.