WntrMute2

Super Member

Before getting too concerned about matching these bypass caps closely, remember that they are being installed in parallel to electrolytic caps and the tolerance range on those is going to be considerably greater than the 100nF value of the caps you are concerned about matching.

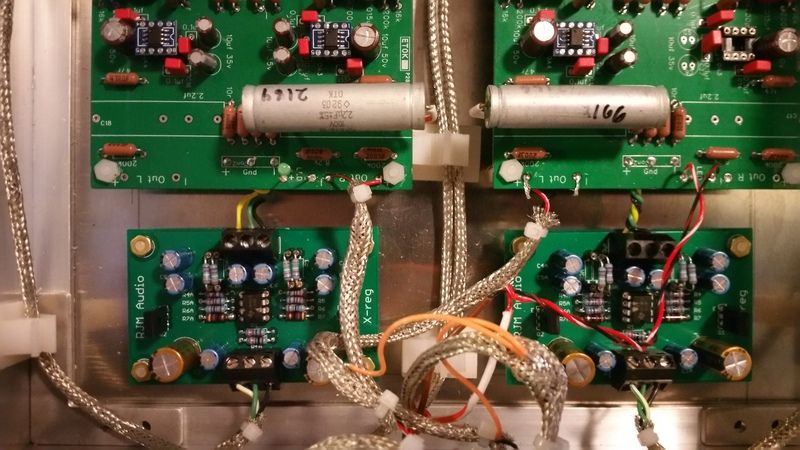

Well, you called that right. The matching for the Elna 10uf 35V caps range from 9.463uf to 9.715uf. The range for the Elna 10uf 50V ranges from 9.364 to 9.583. I bought at least twice as many as I thought I'd need but can't come up with close enough quantities for my dual mono build. Are there caps that have closer tolerances than 20%?