Tube gear rarely uses a lot of shielded wire. I don't honestly know why, but I guess the engineers decided it wasn't needed most of the time. I do have Stromberg-Carlson gear that is loaded with it though. A lot of things get by with nothing more than a grounded lead twisted around the signal wire for shielding and it works out fine in most cases. The metal chassis itself serves as a shield as well. You'd figure with all the high impedance circuits these things would pick up noise like crazy but it just doesn't seem to be the case. Seems like it would make good sense for longer runs from input jacks, but it may not be needed for short internal runs.

One thing I can think of is the way the tube circuit works. The voltage signal in the tube circuit before the output transformer is very high amplitude. The output transformer has a voltage divide ratio like 30:1 or more. So whatever the voltage noise induced into the tube circuit is reduced by the divider ratio of the output transformer. So the effect is a lot less.

Another finer point is noise coupling is like a loop antenna effect like the UHF antenna. The radiation is proportion to the loop area AND the current around the loop. Let's just say the loop area is the same between the tube circuit and the SS circuit. Tube circuit is high voltage swing ( doesn't matter in this context) but low current ( as circuit impedance is high). The magnetic field generates is small as the current is low. So the radiation is weak. In SS circuit, current is high even though the voltage swing is low. BUT loop radiation is ONLY proportional to the loop current ( assume the area is the same). So the radiation from the SS circuit is a lot stronger. So tube circuit is a lot more immure to radiation it this sense........BUT...........

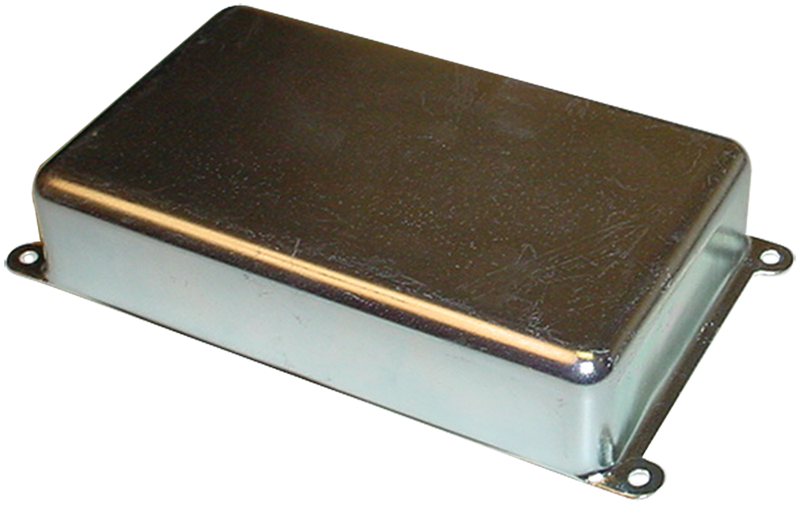

It's not all good news for tube circuits. You have magnetic coupling between the power transformer to output transformer that you don't have in SS amp. I have issue with my kit amp and proven to be crosstalk between the power and output transformer. Once you have the position of the two transformer fixed and if you have problem. You are stuck. So you have a different set of problem with tube amps. This kind of coupling is NOT going to be fixed by shielding. You need thick metal for shielding. In EM theory, it's the EM wave penetration through the material that's the key. The lower the frequency, the longer the wavelength, the thicker the metal has to be to block the radiation. So a normal shield or ground plane on the pcb is not going to do anything. You need a thick metal box.