You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

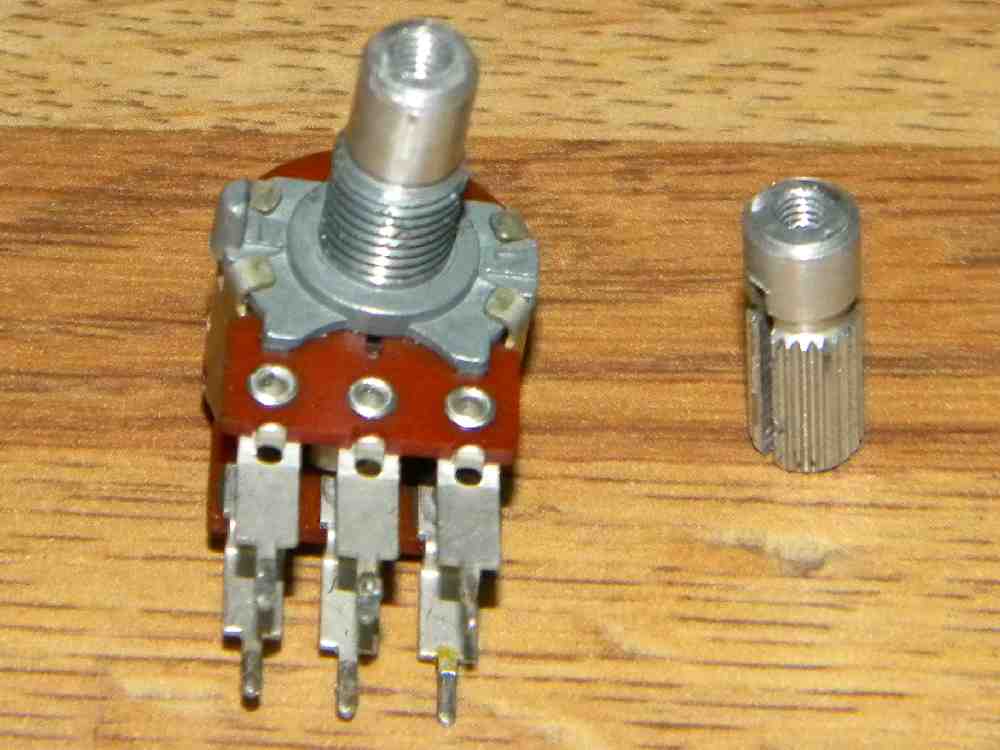

Another Pot Stem Repair

- Thread starter Watthour

- Start date

petehall347

the brandy coffee man

nice job.. would it not have been easier to change the stem ? i know it would mean stripping it down but a clean and grease at same time .. unless of course it was a different length

Watthour

Electron Rancher - JS3600

Holy crap, that's accurate! Great work!

Not really. Chucking the pot is about impossible. The hole is about .004 off center, but probably close enough for what it is. Usually anything that far out would have been scrap.

Pete - If I had the correct stem staking the whole thing through would have been a LOT easier. I almost never get that lucky.

Watthour

Electron Rancher - JS3600

Did you need a drill press to do it? :tresbon:

Mark T.

No. I chucked the threaded portion into a deep/hollow collet on the Hardinge lathe and used the tailstock chuck for the bits (and to start the tap straight). The loose part of the shaft was easy in a standard collet. Feedrate was ultra low to keep the pot from braking out the internal travel stop. I finished tapping by hand and holding the pot shaft instead of the threaded barrel to prevent damage.

As a fellow machinist, I salute your ingenuity. I would definitely consider such a repair rather than replace the pot. Excellent work!

I LIKE MUSIC

Super Member

Great work!

Thanks for the pictures.

Thanks for the pictures.

Nice job! Trying to think about how us mere mortals with 3-jaw chuck lathes might do this. Clamp ring for the pot shaft that is larger in diameter than the pot so it can be chucked and will turn the shaft instead of the pot? I suppose one could use a mill or drill press instead, and use a centering tool to drill the pot shaft (shudder). The repair piece is easy enough with the lathe. Pics of your collet chuck would be appreciated.

Watthour

Electron Rancher - JS3600

GKT - Here's another hint. Chuck the entire pot and use a center drill to start the hole in the aluminum. Remove the pot, clamp it lightly in a bench vise, and restrain the stem with a pair of needle-nosed ViseGrips, then finish drilling and tapping the hole on center. Obviously, the "new" end of the stem is easy right in the chuck.

I would hesitate from putting much force on the mechanical stop within the pot, but a light center drill marking the spot shouldn't place undue stress. We're only going in to aluminum, but we all know how that can grab the tooling.

You could use a 3-jaw internal set but would need to machine one helluva deep/thin step in the reverse side to clear the diameter of the pot housing.

I would hesitate from putting much force on the mechanical stop within the pot, but a light center drill marking the spot shouldn't place undue stress. We're only going in to aluminum, but we all know how that can grab the tooling.

You could use a 3-jaw internal set but would need to machine one helluva deep/thin step in the reverse side to clear the diameter of the pot housing.