I already have a Technics SP10-MK2 which some of you may have seen on some of my posts in the Music forums.

I also have a second SP10-MK2 which I had picked up a few years ago, basically a rescue. After I bought it, it sat in a room where I keep a couple of pieces of gear which are out of rotation but which I refuse to part with (like my Marantz 2245, I bought new back in 1973). I figured one day this spare Technics may come in handy but given the condition it was in, I couldn't possibly display it. A table like this deserves better. It breaks my heart to see such a wonderful and classic piece looking so shabby.

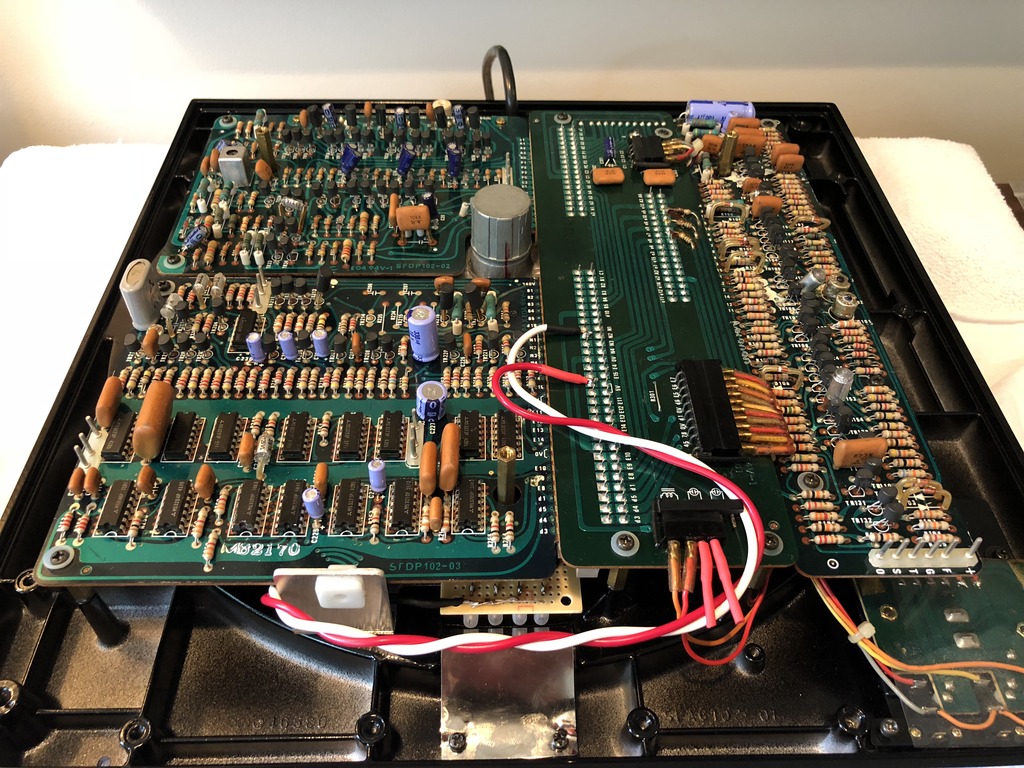

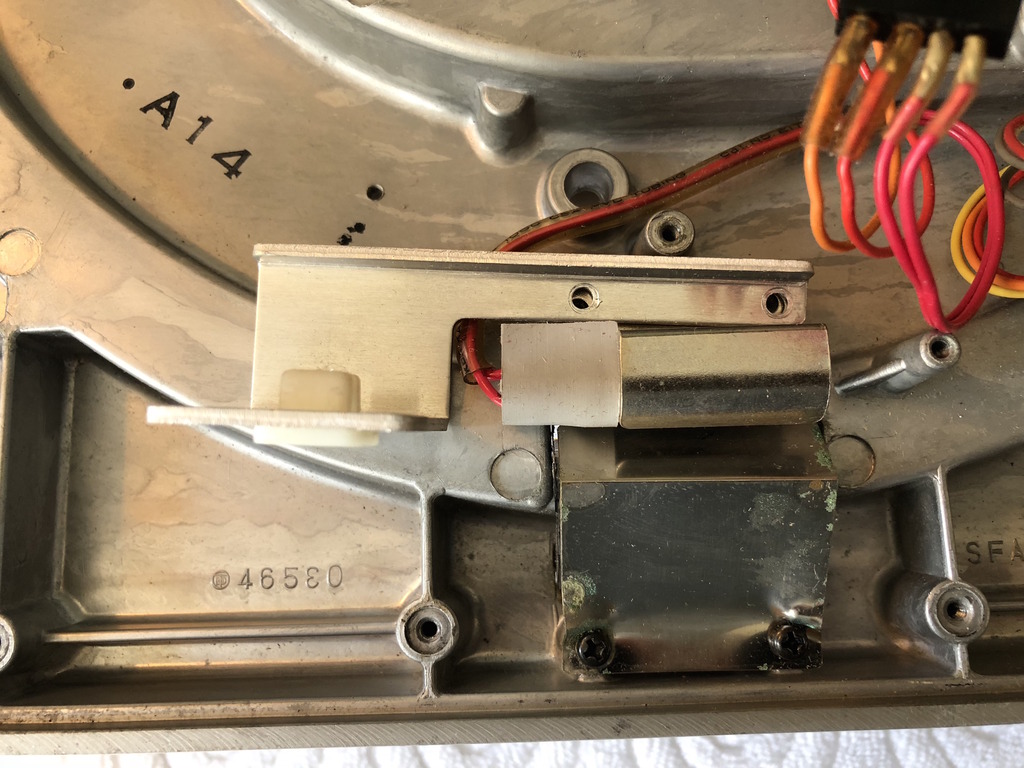

And internally:

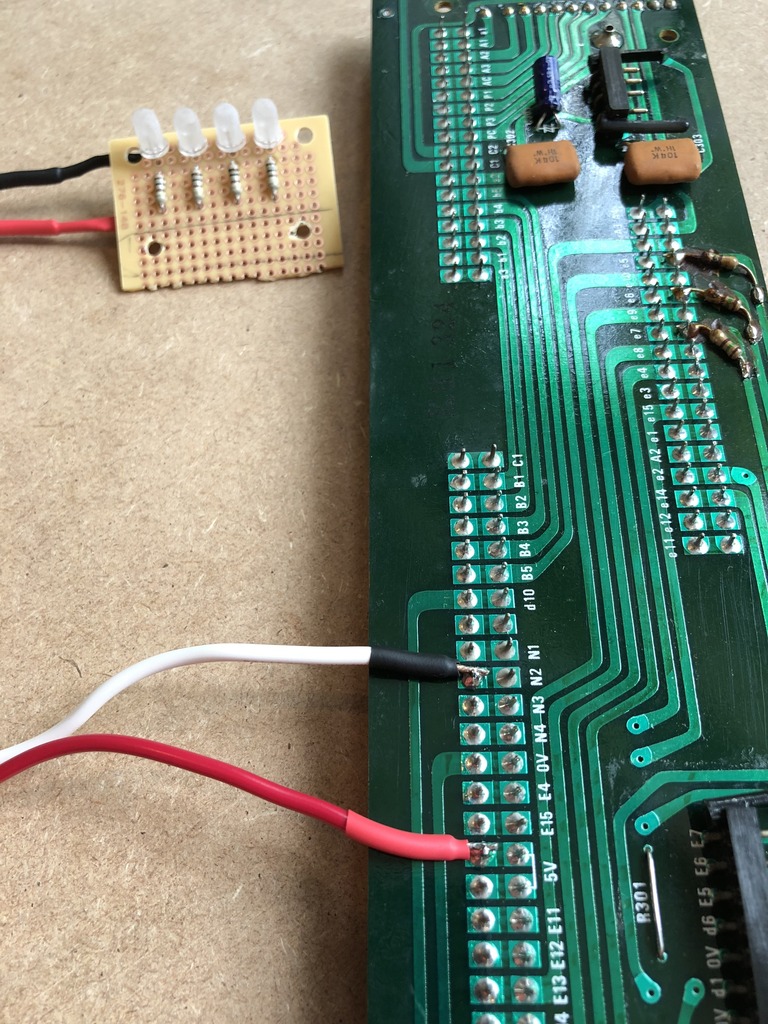

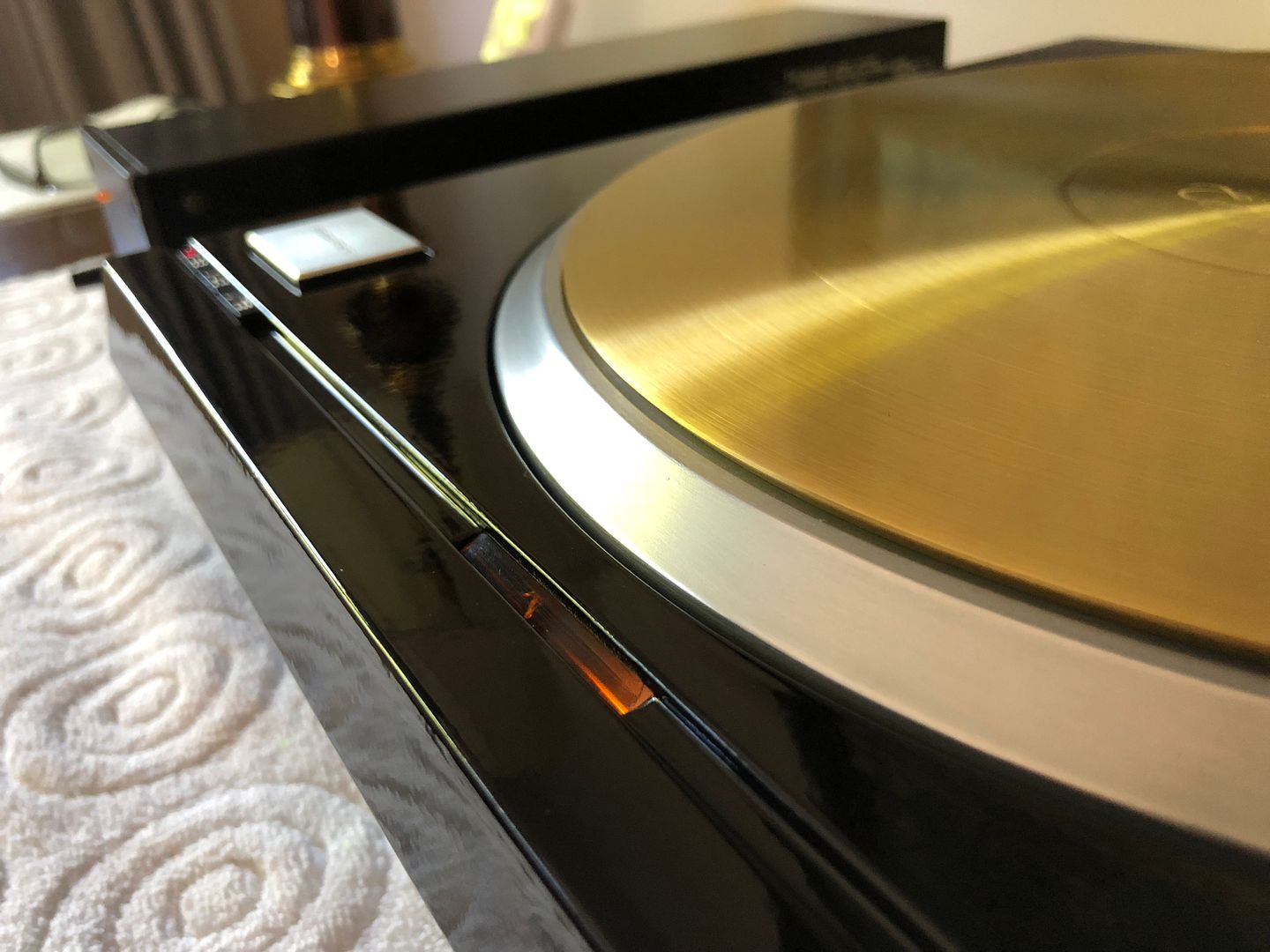

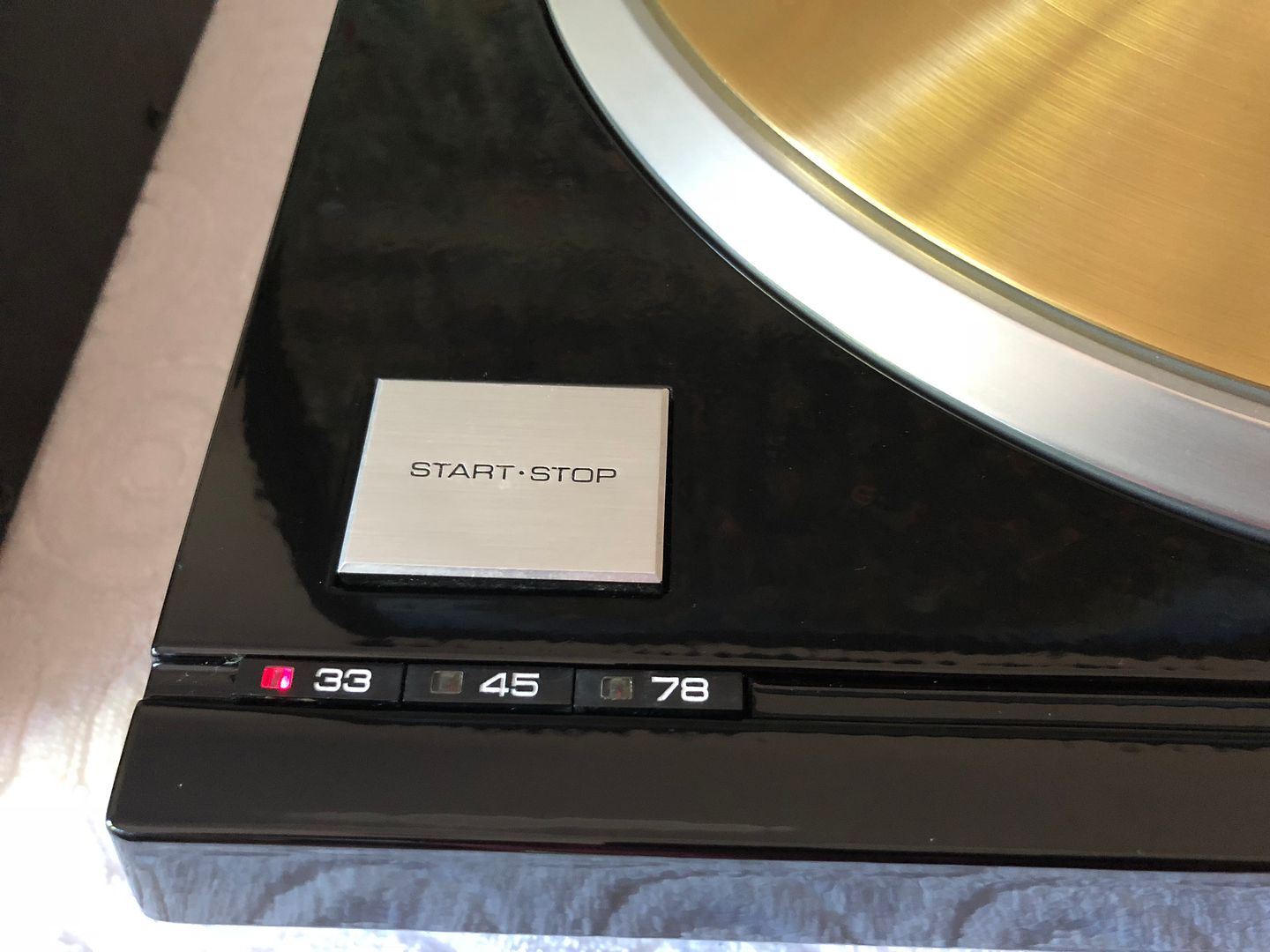

I will be moving into a new office sometime in the coming year so I have been thinking to set-up a little office system and this table will be a part of it. Time to take it apart, remove the four circuit boards, on/off speed switch, strobe and main in:

......

I also have a second SP10-MK2 which I had picked up a few years ago, basically a rescue. After I bought it, it sat in a room where I keep a couple of pieces of gear which are out of rotation but which I refuse to part with (like my Marantz 2245, I bought new back in 1973). I figured one day this spare Technics may come in handy but given the condition it was in, I couldn't possibly display it. A table like this deserves better. It breaks my heart to see such a wonderful and classic piece looking so shabby.

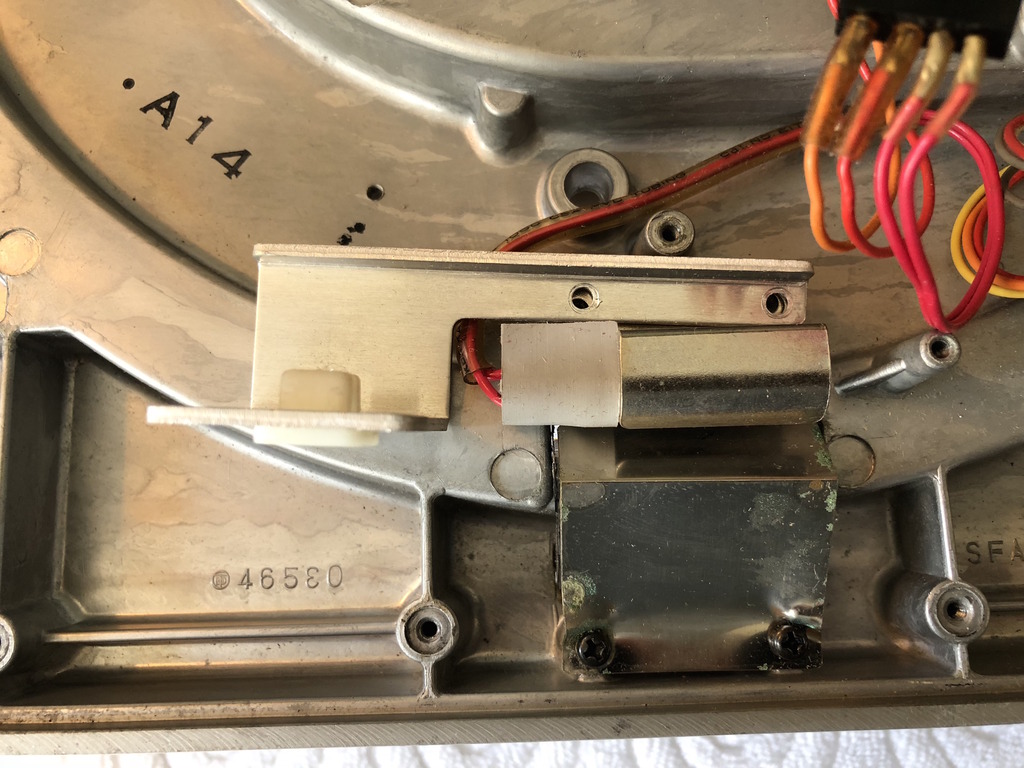

And internally:

I will be moving into a new office sometime in the coming year so I have been thinking to set-up a little office system and this table will be a part of it. Time to take it apart, remove the four circuit boards, on/off speed switch, strobe and main in:

......

Last edited: