Yes, it's bright because of too much current...a short somewhere most likely, but what procedure did you use when installing the trimmers? Some questions...

1. Was that specific amp working when you got it? If so, something you did in your restoration caused this.

2. Did you measure where the originals were set and "preset" the new ones to those readings? Typically, new trimmers will be factory preset at around the mid point, but no guarantees.

3. Did you check the bias when you turned it on on the DBT?

What I'd do to see if it is a bias problem is get your meter set up on the test points prior to turning the amp on on the dbt. You should be able to see what the bias is currently at and start turning it down to 0mV while watching to see if the bulb dims at all. I'm guessing you have a transistor installed incorrectly though.

Search "tickle the dragon" in the Pioneer forum for Mark the Fixer's recommended way of checking/setting bias after an amp rebuild.

1. Was that specific amp working when you got it? If so, something you did in your restoration caused this.

2. Did you measure where the originals were set and "preset" the new ones to those readings? Typically, new trimmers will be factory preset at around the mid point, but no guarantees.

3. Did you check the bias when you turned it on on the DBT?

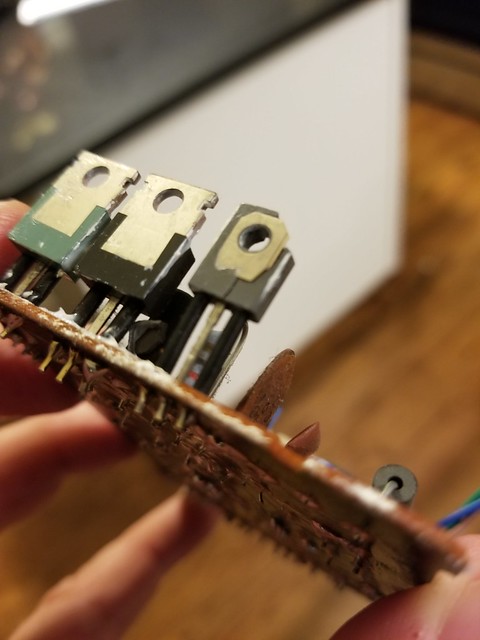

What I'd do to see if it is a bias problem is get your meter set up on the test points prior to turning the amp on on the dbt. You should be able to see what the bias is currently at and start turning it down to 0mV while watching to see if the bulb dims at all. I'm guessing you have a transistor installed incorrectly though.

Search "tickle the dragon" in the Pioneer forum for Mark the Fixer's recommended way of checking/setting bias after an amp rebuild.

Last edited: