Hi All, been following this thread and a couple others on Pinkfish / VinylEngine on these old Kenwood / Trio Belt Idler turntables. I recently picked up an PC-350--which was in a console for 50 years. After a good, thorough cleaning and sourcing a bunch of upgrades--still working on the lubrication maintenance.

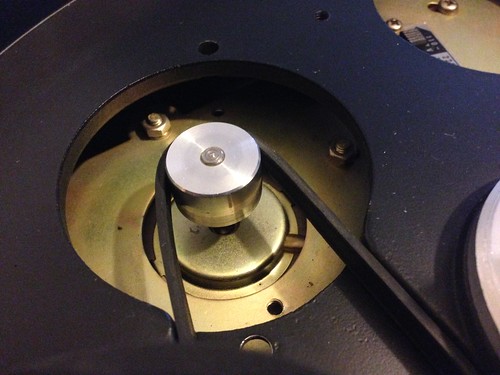

I am good with most elements of this machine--but am trying to nail down what to use to lubricate the idler bearings. I've broken them open, cleaned out all the grease, found some replacement (delrin) thrust pads and need to re-pack the bearing. The large, main bearing was filled with white grease that had a bunch of black streaks in it that presumably came from a disintegrated thrust pad (none was found within) or some mixed motor oil. The smaller bearing was nearly dry--but had a cracked thrust bearing within.

I have read that any number of things could be used to pack the bearings--but can't find consensus. And can't find squat about amount to input.

- The first page of This post talks about using CV joint grease--but some type not available in the states (post was 9 years ago).

- The second page of the same post suggested soaking in Shell Formula 5W-20 motor oil then packing with Honda Pro Molybdenum Disulfide grease

My inclination is to pack it with White Lithium Grease, dip the shaft in lightweight motor oil, then insert and seal the bearing. Thoughts on this procedure?

I am using sewing machine oil for the motor, but not sure how much to put in the bath to properly be absorbed by the wicks and bathe the motor.

Questions:

- How different is the Honda Pro grease vs White Lithium Grease ? Interchangeable? Would you recommend something else?

- Do I use the same method for both the large and smaller bearings?

- Do I just pack it as full as possible or do I leave some breathing room?

- How much oil do I use to properly bathe the motor? So far, filled it up once and let it be absorbed. More?

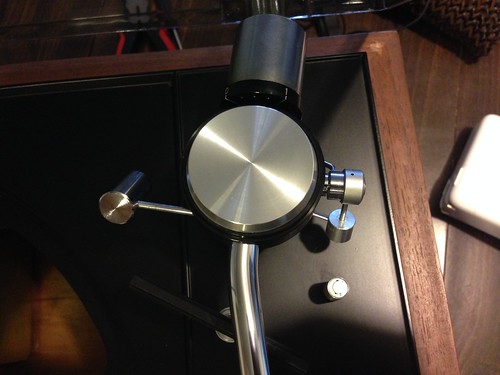

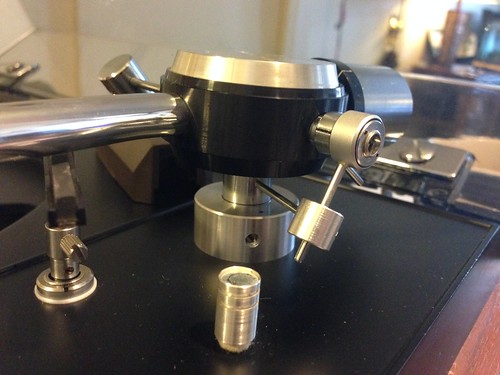

Added a bunch of labeled pictures. (I wish I had these when I started!)

Passing along some upgrades / things I purchased. I am still in upgrade mode--so just bought these, haven't installed or tested yet. I'll return back with updates.:

- This tonearm is extremely back-end heavy--so I picked up a used ~13 gram AT headshell (LT-13) on ebay to counterbalance the fat ass. Previous Owner had a soft metal piece just taped to the lightweight Kenwood headshell ($50 shipped)

- I did buy a replacement belt from LP Tunes--although realizing that the original silicone one I have still looks good, so will keep for a backup. I haven't tested it yet, but is much less wide than the silicone although looks like an exact length. ($24 shipped)

- I will take the capacitor off and test value. Picked up a replacement .oo47 uf / 640v from tubes and more. ($5 shipped)

- Picked up replacement RCA cables w/ ground. (this requires soldering--but super simple). Bought 8ft from ebay endtoendcables. ($52 shipped)

- The most difficult pieces to source specifically for this were the delrin thrust pads. It needs (for the large = 4mm x 19mm, for the small 2xmm x 12mm). I found other delrin pads on ebay from a couple sellers, but no direct matches for size, so found the seller, Pat, that makes them and was recommended the following:

- Pioneer PL-50A ( 2.3mm x 19mm) FOR LARGE

- Empire 208 ( 2mm x 11.4mm) FOR SMALL

- I bought 2 of the Pioneer PL-50A's to stack and one Empire ($60 shipped - way more than these should cost, but Pat helped me out with sizes, so you know)

- While a lid isn't 100% necessary, I wanted one and mine had its removed and discarded by the previous owner because it needed to fit in their console. Have the hinge holes, but have 0 hope that I'll ever find hinges--so just looking for one to place on it for now like I do with my 1200's. Was looking to get a custom one made from jnbaudio for $175, but just purchased a used one that is supposed to fit an Ion. Same specs although it has a tonearm bump. It looks modern / rounded and not sure how that will match the style of this vintage TT, but worth a shot. Size is about 14.25"x17.25" ($33 shipped)

Appreciate any help you can provide!

IMG_0338

IMG_0338 IMG_0340

IMG_0340 IMG_0339

IMG_0339 IMG_0337

IMG_0337