MCM_Fan

AK Subscriber

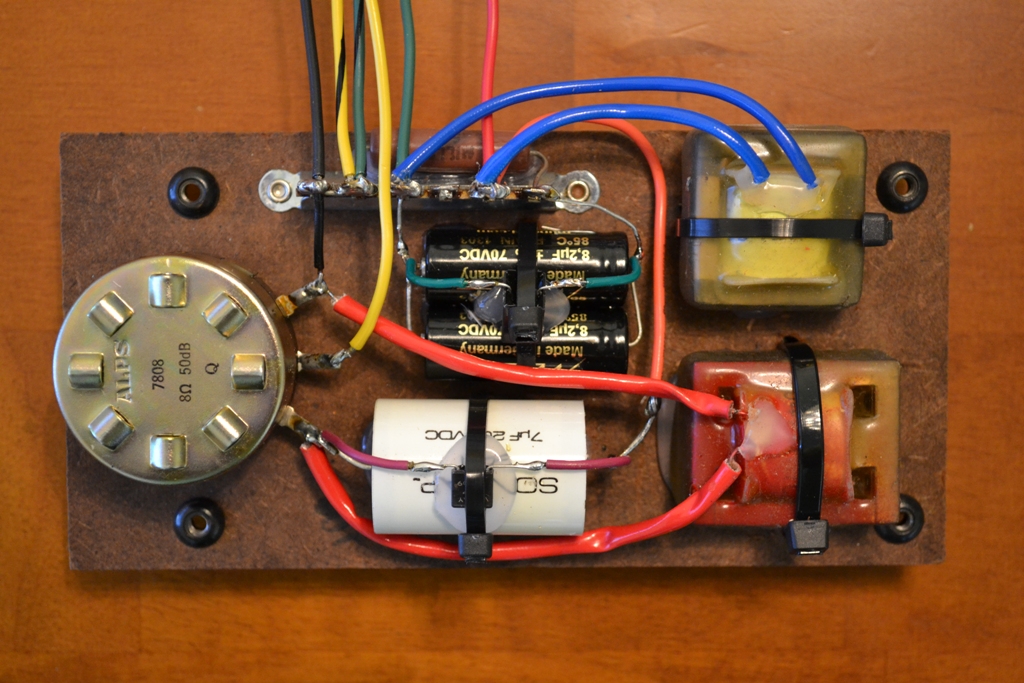

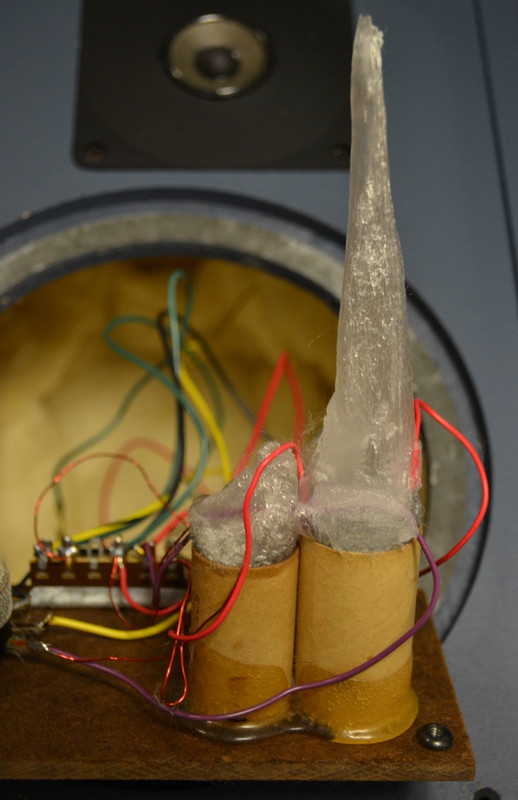

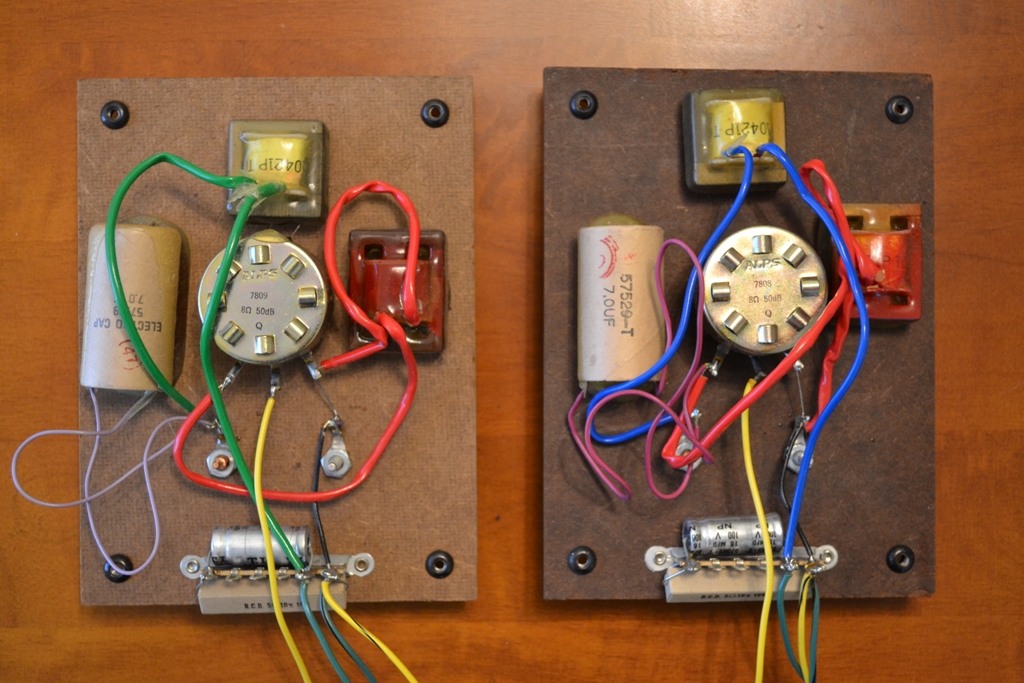

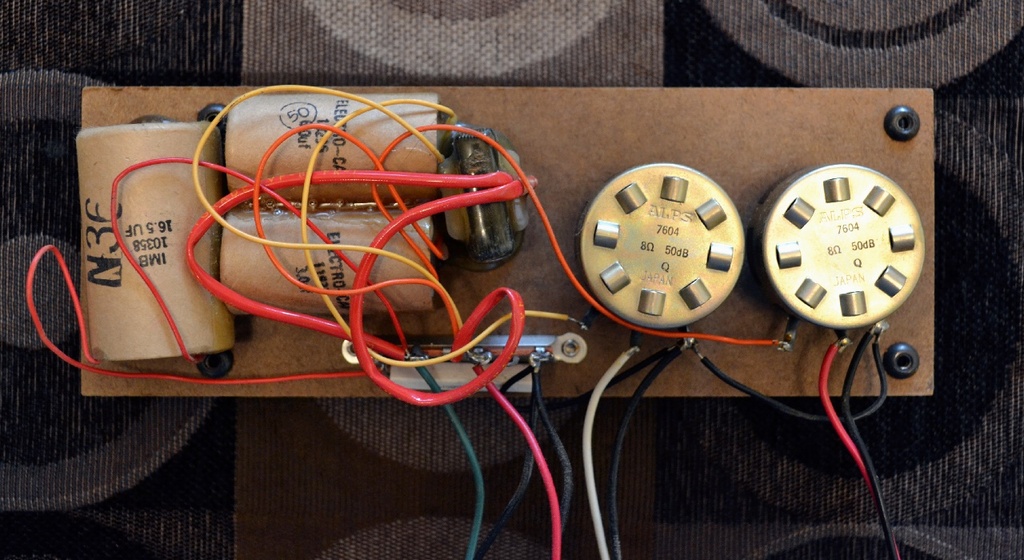

How critical is inductor lead length in a crossover network? I've only seen three pairs of JBL crossovers (L36 Decades, 4301B Control Monitors and L19s) in the flesh and all had what appeared to be excessively long leads on the inductors. Certainly much longer than necessary to make the connections to the other components and terminal strips.

I'm currently recapping the crossover networks for my 4301B Control Monitors with new caps, but borrowing the inductors and L-pads from a pair of L19 crossovers. My first instinct was to trim the leads to tidy things up. This would shave about an inch and a half off the leads of the inductor in the tweeter circuit and 2.5" - 3" off the leads of the inductor in the woofer circuit.

But, before doing so, I thought I'd ask. Will shortening these leads have any negative impact on the performance? It seems weird to me that they were all so excessively long. Any conductor with current flowing through it acts as both a radiator and an antenna. I've always been told it's best to keep lead wires as short as possible to keep them from generating/picking up noise. But, will shortening them alter the DCR or inductance of the inductor enough to audibly impact performance?

I measured the length of all of the inductor leads in my L19 and 4301B crossovers and all (8 inductors = 16 lead wires) were between 6" and 6 1/4". Knowing that JBL used the same components in many different designs, it makes me wonder if they just speced all inductor lead wires as 6" so they would be long enough for all their different models. In other words, for assembly/cost reasons, not electrical performance.

I look forward to the responses. I'm a little OCD when it comes to clean looking crossovers. So, as said, my impulse is to trim the leads, but sound quality always comes first. Once they are re-installed in the cabinets, no one else will see them. So I'm ultimately more concerned about the potential for picking up noise vs. changing the DCR of the inductors.

What say you? Trim them or leave them long? Why/why not?

I'm currently recapping the crossover networks for my 4301B Control Monitors with new caps, but borrowing the inductors and L-pads from a pair of L19 crossovers. My first instinct was to trim the leads to tidy things up. This would shave about an inch and a half off the leads of the inductor in the tweeter circuit and 2.5" - 3" off the leads of the inductor in the woofer circuit.

But, before doing so, I thought I'd ask. Will shortening these leads have any negative impact on the performance? It seems weird to me that they were all so excessively long. Any conductor with current flowing through it acts as both a radiator and an antenna. I've always been told it's best to keep lead wires as short as possible to keep them from generating/picking up noise. But, will shortening them alter the DCR or inductance of the inductor enough to audibly impact performance?

I measured the length of all of the inductor leads in my L19 and 4301B crossovers and all (8 inductors = 16 lead wires) were between 6" and 6 1/4". Knowing that JBL used the same components in many different designs, it makes me wonder if they just speced all inductor lead wires as 6" so they would be long enough for all their different models. In other words, for assembly/cost reasons, not electrical performance.

I look forward to the responses. I'm a little OCD when it comes to clean looking crossovers. So, as said, my impulse is to trim the leads, but sound quality always comes first. Once they are re-installed in the cabinets, no one else will see them. So I'm ultimately more concerned about the potential for picking up noise vs. changing the DCR of the inductors.

What say you? Trim them or leave them long? Why/why not?

Last edited:

, My JBL Lancer 66's longest leads were on the caps. More than twice the length of any other connection.

, My JBL Lancer 66's longest leads were on the caps. More than twice the length of any other connection.