Drummerboy2

Well-Known Member

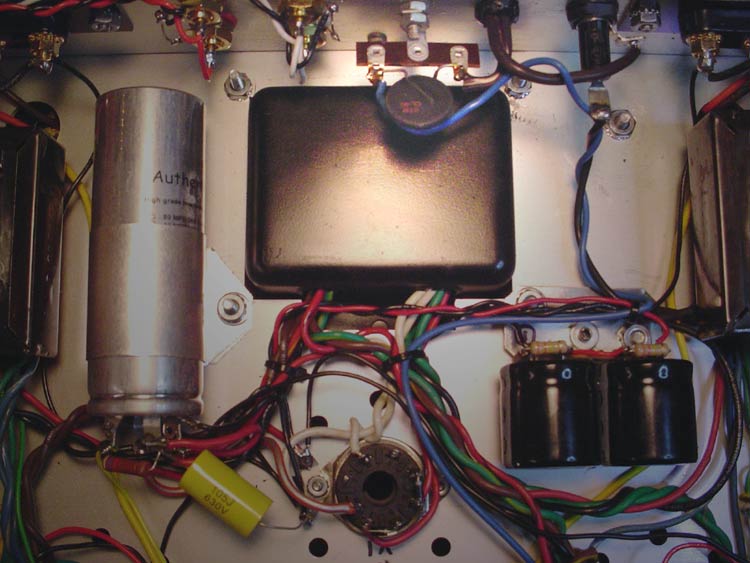

So I will finally be getting a Tube power amp.  I called Bob and we spoke for a while on the phone and he answered all of my question I had. Very nice man! I have been wanting a nice tube power amp for a while but the prices are just too much for the amount of power you are getting. So I have been looking/reading all I could find on the Bob Latino VTA-120 tube power amp and finally purchased one.

I called Bob and we spoke for a while on the phone and he answered all of my question I had. Very nice man! I have been wanting a nice tube power amp for a while but the prices are just too much for the amount of power you are getting. So I have been looking/reading all I could find on the Bob Latino VTA-120 tube power amp and finally purchased one.

I was going to go for the M125 but I will be building a pair of 2 way GPA drivers with a Zilch Z19 xover so the VTA-120 should be enough for my setup.

I will be using the GZ34 (JJ, Mullard, and Ruby) rectifiers with this amp. I got the Cap upgrade also!

Any thing else to add?

Thanks

I was going to go for the M125 but I will be building a pair of 2 way GPA drivers with a Zilch Z19 xover so the VTA-120 should be enough for my setup.

I will be using the GZ34 (JJ, Mullard, and Ruby) rectifiers with this amp. I got the Cap upgrade also!

Any thing else to add?

Thanks

Al

Al