Hoodcom

Well-Known Member

Pioneer SX-1250 restoration project -Update: Protection Issue?

I'm finally getting to the restoration of this 1250 I have here.

So let's start off with a list of known problems that I know of at this time...

When I first got it, I pretty well found out that it does power up, but has no sound.

NONE of the fuses in it are blown, all test good with my digital multi meter.

Currently, I can not power it up, until I get the new rear outlet in to replace the broken one, due to safety reasons.

It is dirty on the inside, but nothing appears to be scorched / burnt on ANY circuit boards.

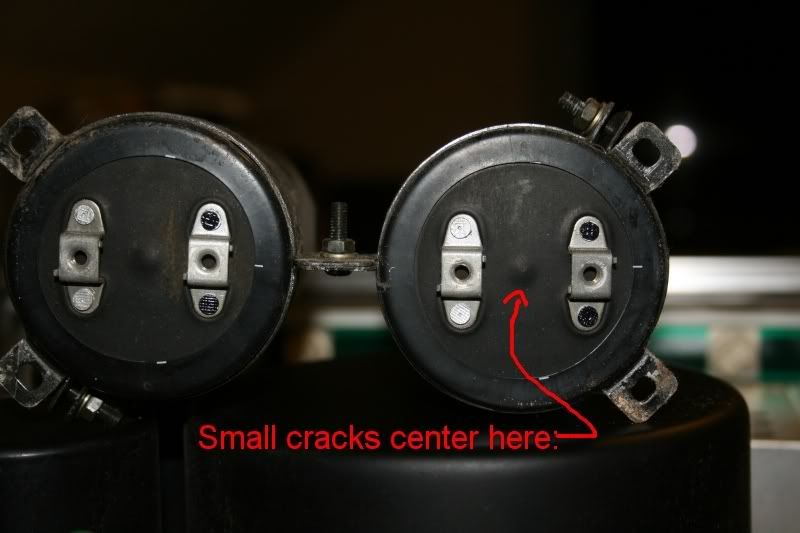

The last picture I posted in this post HAS something that may need to be looked at, but I don't know for certain...

One large capacitor... well, I can't tell if it leaked or what, but...

.........what is this blue gunk?

Other than that, I do not know what the problems could be nor can I test for live voltage at this point, but can when I can have it safely powered up when the replacement outlet arrives.

I should be able to do any testing that doesn't require power being fed, though.

Also, since I have it apart, it probably wouldn't hurt to recap the more critical components incase that is the cause of the "no sound" issue here.

Now, part of this restoration will cover cosmetic issues as well, and clean up. This unit will not be perfect or mint, but it will be good enough, I hope.

Things on my list to do for it so far, is:

So far that I can think of from the top of my head.

So now for pictures...

Rough shape, I know. :tears:

As seen here, a replacement pot for the bass control:

I got the power cord fixed, but shall wait for the AC outlet now...

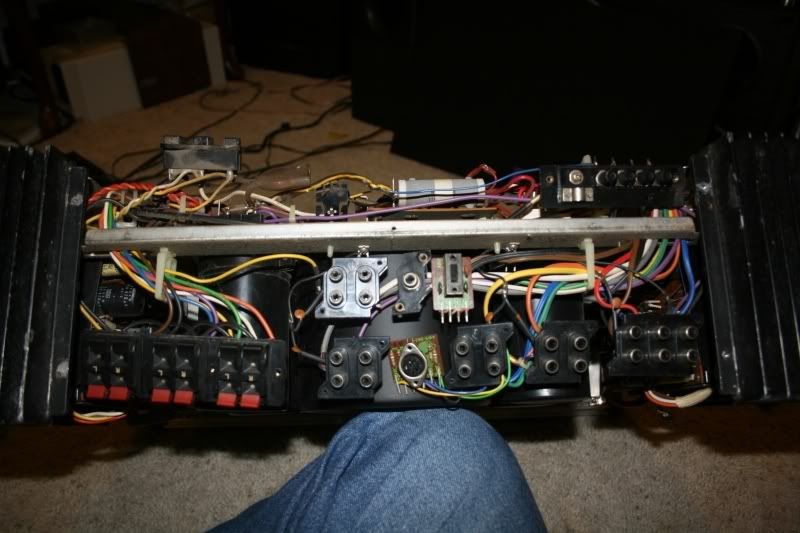

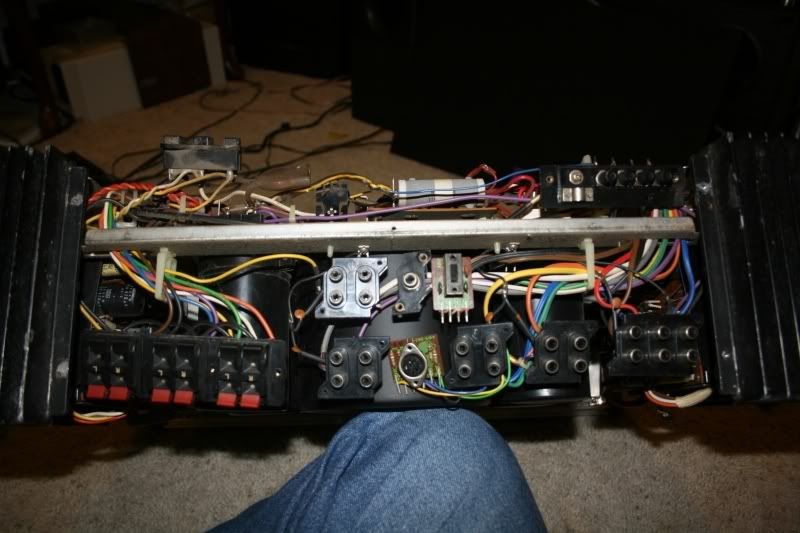

Here's the bottom...

Top with covers off...

Here are these boards here...

Got the rear panel off, so I can have it ready for cleaning and for easier access to replace the AC outlet...

Current AC outlet, mounting is broken, which is a hazard due to being able to be pushed inward, and I will NOT have a hazard out of this, which is why I refuse to power it until I have it replaced... safety first.

The other side here....

And here's the 1250 on it's side on the sofa table, resting safely on a thick towel so I don't scratch the sofa table...

...whether or not I need to worry about this... it WAS mounted well still... would it be alright still or is this a real problem?

For the time being, I will remove the other power amp board and see what I can do for cleaning.

I'm finally getting to the restoration of this 1250 I have here.

So let's start off with a list of known problems that I know of at this time...

When I first got it, I pretty well found out that it does power up, but has no sound.

NONE of the fuses in it are blown, all test good with my digital multi meter.

Currently, I can not power it up, until I get the new rear outlet in to replace the broken one, due to safety reasons.

It is dirty on the inside, but nothing appears to be scorched / burnt on ANY circuit boards.

The last picture I posted in this post HAS something that may need to be looked at, but I don't know for certain...

One large capacitor... well, I can't tell if it leaked or what, but...

.........what is this blue gunk?

Other than that, I do not know what the problems could be nor can I test for live voltage at this point, but can when I can have it safely powered up when the replacement outlet arrives.

I should be able to do any testing that doesn't require power being fed, though.

Also, since I have it apart, it probably wouldn't hurt to recap the more critical components incase that is the cause of the "no sound" issue here.

Now, part of this restoration will cover cosmetic issues as well, and clean up. This unit will not be perfect or mint, but it will be good enough, I hope.

Things on my list to do for it so far, is:

- Re-cap (Could help fix any current electronical issues)

- New faceplate (Have one on the way)

- Replace rear AC outlet

- Replace inner tuning scale and tuning needle

- fix the paint job on the heatsinks

- Get the wood cover looking good again

- few other cosmetic things

- clean up the receiver

- replace the bulbs

So far that I can think of from the top of my head.

So now for pictures...

Rough shape, I know. :tears:

As seen here, a replacement pot for the bass control:

I got the power cord fixed, but shall wait for the AC outlet now...

Here's the bottom...

Top with covers off...

Here are these boards here...

Got the rear panel off, so I can have it ready for cleaning and for easier access to replace the AC outlet...

Current AC outlet, mounting is broken, which is a hazard due to being able to be pushed inward, and I will NOT have a hazard out of this, which is why I refuse to power it until I have it replaced... safety first.

The other side here....

And here's the 1250 on it's side on the sofa table, resting safely on a thick towel so I don't scratch the sofa table...

...whether or not I need to worry about this... it WAS mounted well still... would it be alright still or is this a real problem?

For the time being, I will remove the other power amp board and see what I can do for cleaning.

Last edited: