The more amplifier building that I've done, the more that I have progressed to seeing it as an art more so than a science. The science (electrical engineering) part of it is pretty simple to me these days, but the art of it is something I am seeking to master.

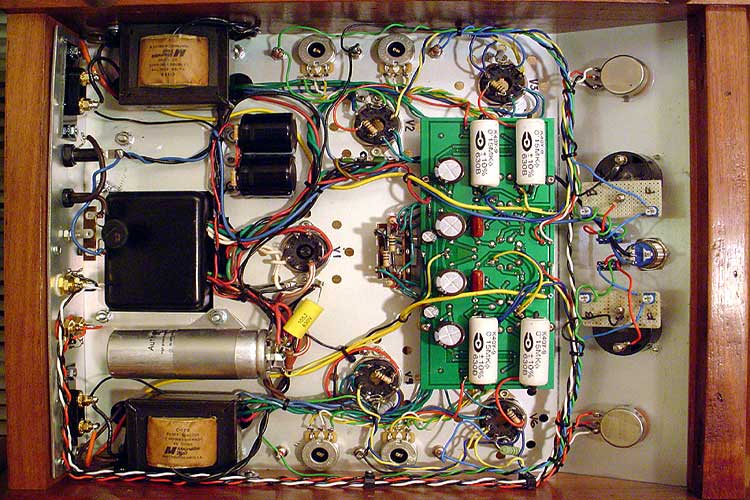

For example when I see a well laid out physical design with right angle wiring like in the attached pictures, I feel a burning desire to slow down and focus on building pieces of art myself. Maybe my issue is I'm more of an engineer than an artist (can't draw to save my life), but I have to believe there is hope...

Looking for any tips or suggestions on how to best layout amplifier design (i get the electrical aspects - input far from power supply, etc) for aesthetics and wire layout. Also, tips on how to make & run these 90 degree wires & leads in such a beautiful fashion are welcomed as well. Would love to learn to do wire wrapping like the old masters did (WE, etc.)

Just trying to take my game to another level.

Thanks,

Mark

For example when I see a well laid out physical design with right angle wiring like in the attached pictures, I feel a burning desire to slow down and focus on building pieces of art myself. Maybe my issue is I'm more of an engineer than an artist (can't draw to save my life), but I have to believe there is hope...

Looking for any tips or suggestions on how to best layout amplifier design (i get the electrical aspects - input far from power supply, etc) for aesthetics and wire layout. Also, tips on how to make & run these 90 degree wires & leads in such a beautiful fashion are welcomed as well. Would love to learn to do wire wrapping like the old masters did (WE, etc.)

Just trying to take my game to another level.

Thanks,

Mark

Last edited: