rufleruf

Poor Impulse Control

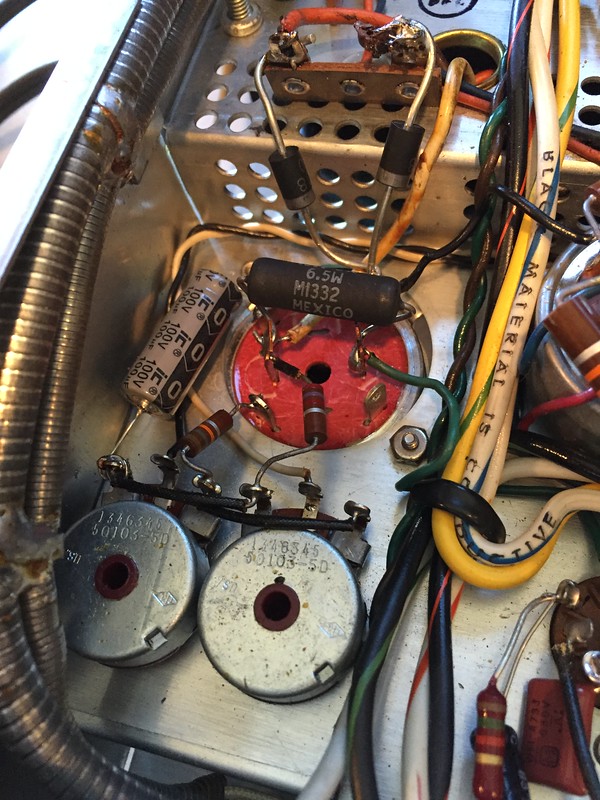

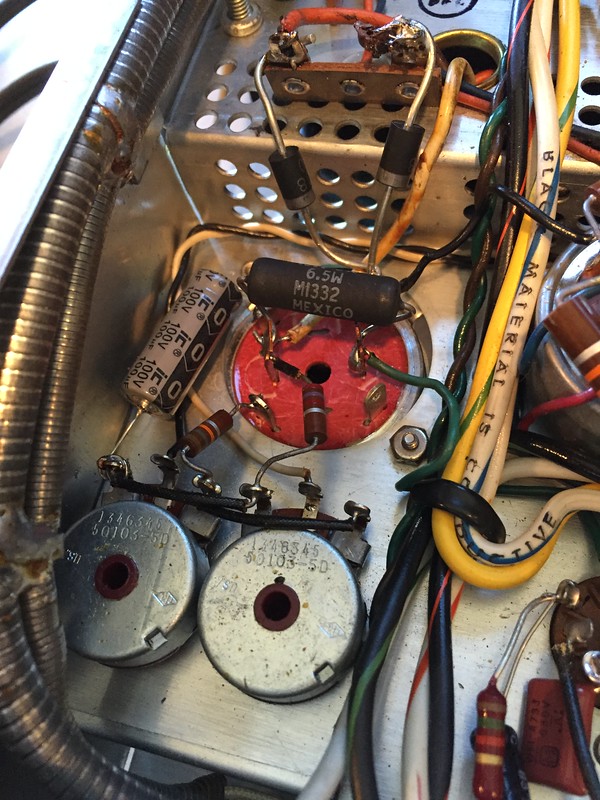

I bought a 2x 1000uf x 50V can cap from a well known seller to install in my working X202B - caps C53A & B. Installed it last night, also replacing the 2 diodes (SR3 & SR4) that go to the can (+ side) and R121 a 15 ohm, 7W resistor that bridges the negative side of the two 1000uf's. Replacement is a 6.5W item.

It passed DBT, so I powered it up on my variac. After about 2 minutes and at maybe 70% on the variac the can cap popped and shot some smoke out.

I'm suppose there are three possible failure modes: the can was defective in some way, it saw more than 50V, or it saw more amperage than expected.

I had maybe an hour of listening on this unit since a recap, I just thought replacing this cap would be a good idea.

Anyone care to guide me in some testing before I attempt a repair? From pin 4 of one of the 12AX7's to the junction of the diodes and the common + of C53 I get about 7.5VDC at 70% - seems reasonable. I guess it's probably a matter of current - maybe I need a current meter.

It passed DBT, so I powered it up on my variac. After about 2 minutes and at maybe 70% on the variac the can cap popped and shot some smoke out.

I'm suppose there are three possible failure modes: the can was defective in some way, it saw more than 50V, or it saw more amperage than expected.

I had maybe an hour of listening on this unit since a recap, I just thought replacing this cap would be a good idea.

Anyone care to guide me in some testing before I attempt a repair? From pin 4 of one of the 12AX7's to the junction of the diodes and the common + of C53 I get about 7.5VDC at 70% - seems reasonable. I guess it's probably a matter of current - maybe I need a current meter.