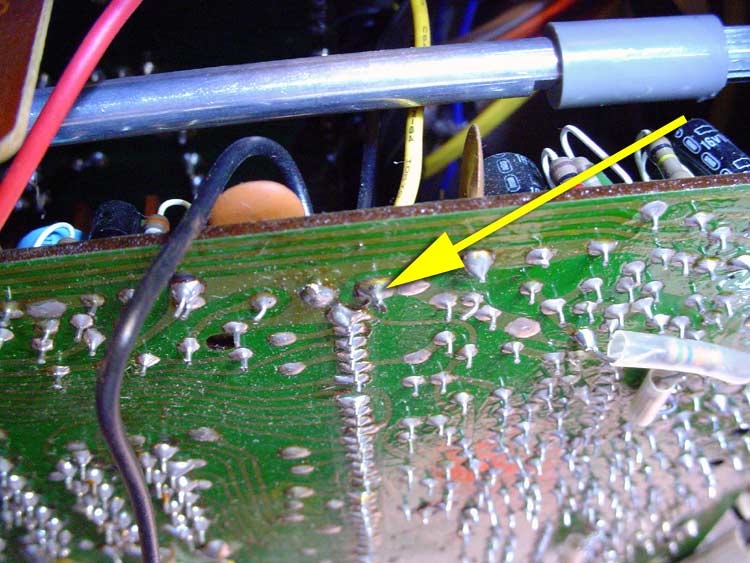

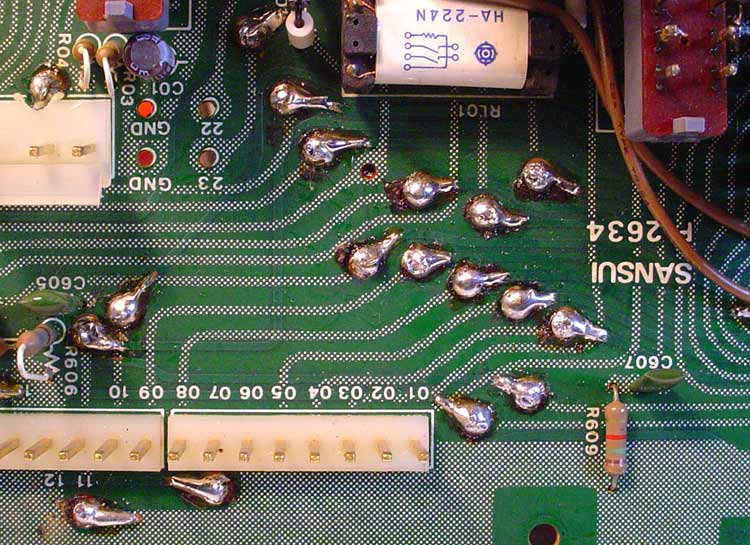

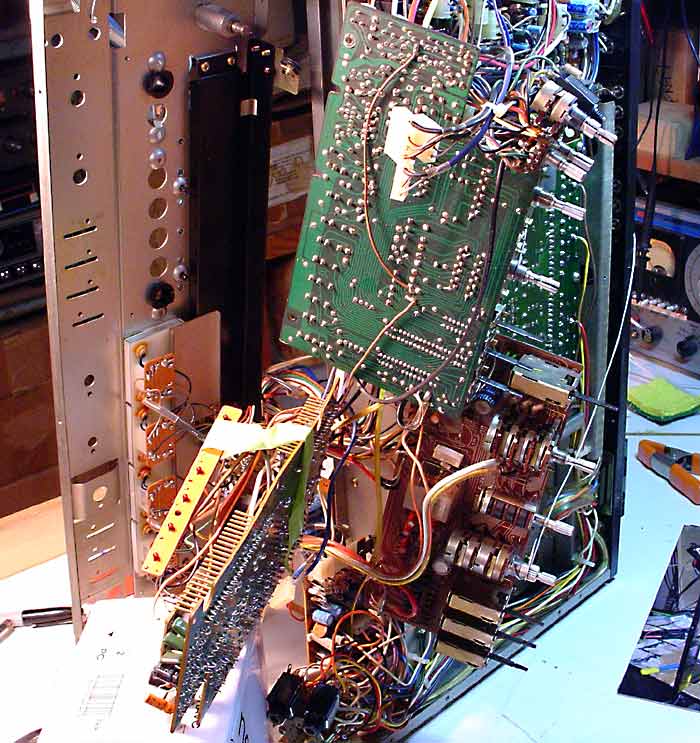

Hoping someone can help me dig myself out of a rookie blunder here. Thx much. I removed my dolby board to resolder the pass-thrus that fail and Unfortunately I created a problem for myself. I had sketched out where all the connections that I desoldered ran between boards, etc. Here's my open issue - I need to confirm where yellow wire # 17 from F-2653 selector board runs to on F-2655 board. I blew it on my sketch. I think it leaves that board on the wiring diagram as a "C" designator that ends up running to board F-2655 Dolby Board but I can't locate what looks like it should be pin or thru hole 701 to connect it to. On the other wire # 18 orange conductor running from the F-2653 selector board, I show it should end up on the F-2654 push button switch board at thru hole 710 if I have it right. Can't believe I botched this up, losing my edge here. So, my issue is the two wires #17(yellow)and #18(orange) routing from the F-2653 selector board to wherever they're actually supposed to end up.

help!

help!

;-}

;-}