sKiZo

Hates received: 92644 43.20°N 85.50°W

Spring Planting Season

... is over. That was my main excuse for putting this little project on hold for a while. Hotter than hello outside today, so a good day to stay inside.

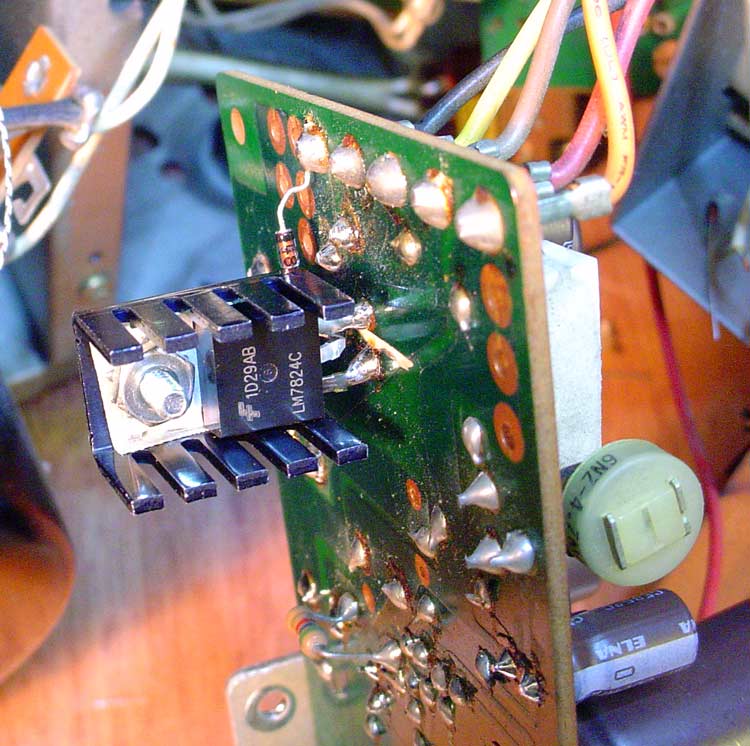

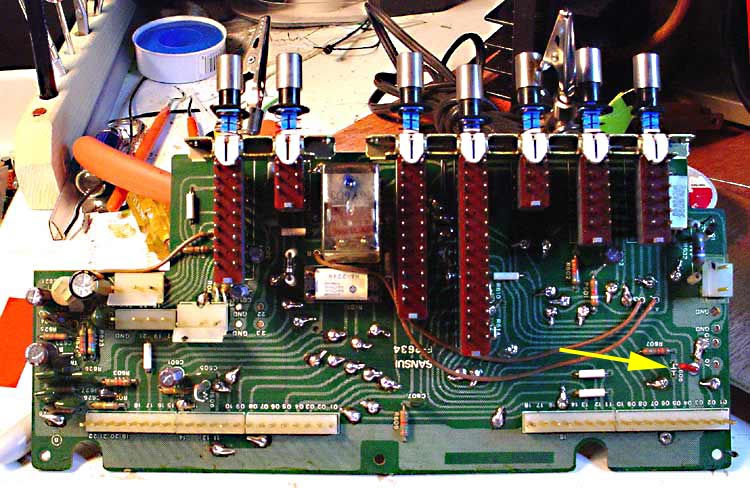

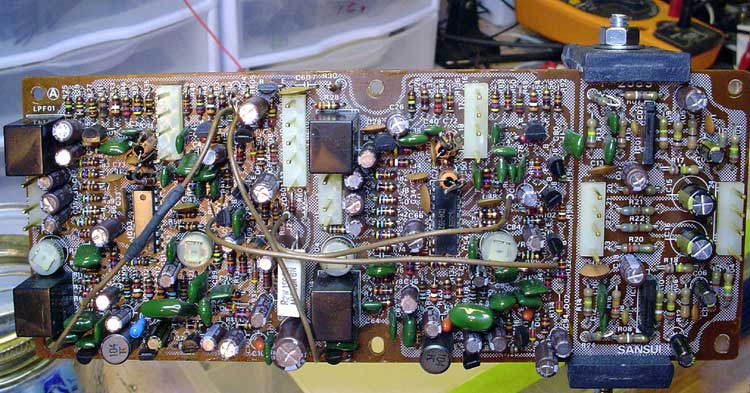

Got started on pinning the switch board. One special tool is turning out to be real handy - I ground the end flat on a small pointy XActo blade and thinned that down for scraping copper traces. I also ground the rest of the sharpened edge so I don't end up slicing and dicing my fingers while working with it.

Started on some of the easy to get to pass throughs.

One thing I found out real quick - I'm out of practice. Haven't managed to burn thru anything I'm not supposed to yet, and the tin shields are a big help there. Just cut them as needed from some roof flashing and bend them over the sensitive bits.

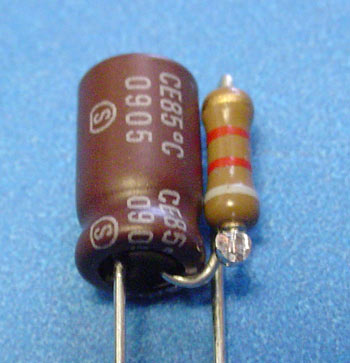

For pins, I used clippings from capacitors that I've been collecting for just this job. I found out fast that it works better if I bend a little "J" hook in the first end. Basically just bend the wire against itself over some needlenose pliers, then bend it back out leaving a small loop that will stand proud of the solder pad. That helps to get the wire flat to the trace.

It's a four step process - for me anyway ...

- Lightly solder the bent wire into the hole, then use my handy dandy XActo scraper to push the wire tight to the trace. The "J" hook makes this easy to clear any ridge around the hole and get a nice tight fit. Also allows you to fine tune the wire so it matches the trace.

- Solder the wire to the scraped trace and top off the blob over the pass through point. Dragging the iron tip back from the blob over the wire gives a nice clean joint.

- Flip the board over, press the wire tight on that side and bend the wire to follow the scraped trace. Solder that same way the front was done. That's another point where that "J" loop on the front is handy - it adds a bit of spring tension to keep the wire tight and properly aligned to the traces on both sides when you reheat the joint.

- Double check the other side of the board. I had a couple joints bubble a bit. A quick touch up with the iron cleaned those up nice.

PS ... thanx everybody for talking me into the 40W Radio Shack desoldering tool. The 30 watter I'd been using wasn't quite hot enough to clean out the big blobs from the old pass through joints. Real easy to work with too.

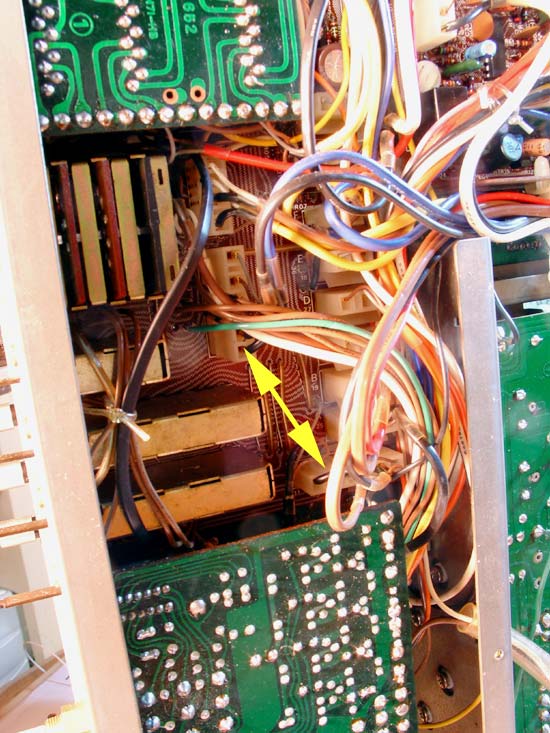

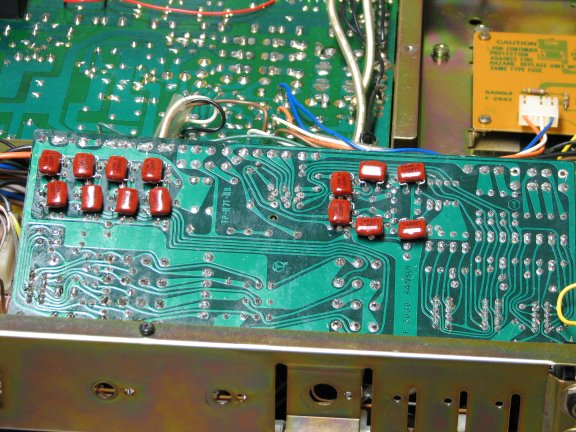

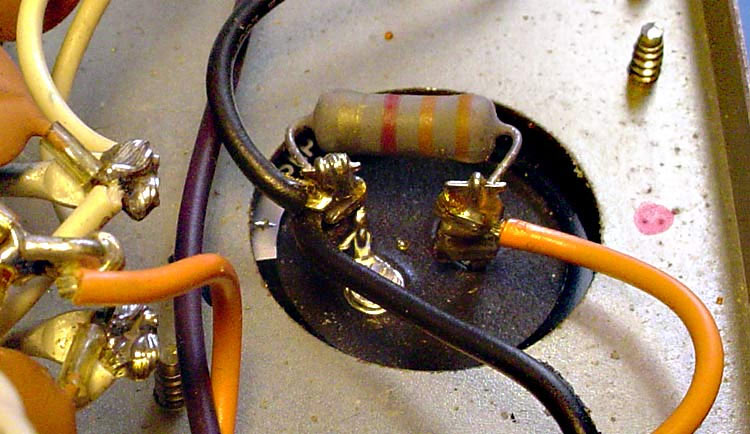

About the arrow ... what the futterwaken is that?? It's soldered on the backside, but I see nothing for it to connect to on the front. One of those Sansui gotchas? As in ... well ... we thought we'd need one there but decided against it? Here's what it looks like from the other side after pinning.

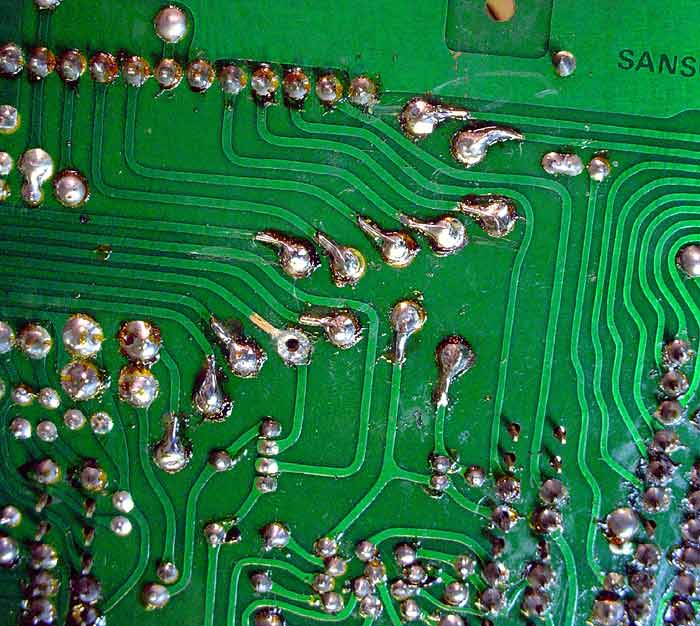

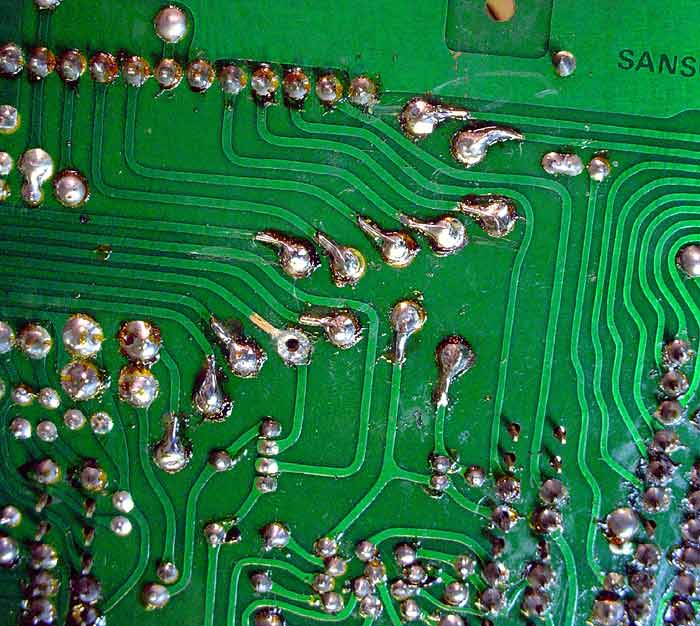

If nothing else, it shows one of the scraped traces ready for a pin. Takes a light touch, so easy does it is the rule. I expect I'll just resolder the blob to nowhere before I pack it up. Still be interesting to find out if anyone else figured it out.

********

13 joints down - and depending on who you listen to - 37 or 39 more to go.

And another PS ... my cute lil holding jig for the board wasn't quite as handy as I thought it would be. It certainly had it's uses, but half the work was done propping the board up with a coffee can.

... is over. That was my main excuse for putting this little project on hold for a while. Hotter than hello outside today, so a good day to stay inside.

Got started on pinning the switch board. One special tool is turning out to be real handy - I ground the end flat on a small pointy XActo blade and thinned that down for scraping copper traces. I also ground the rest of the sharpened edge so I don't end up slicing and dicing my fingers while working with it.

Started on some of the easy to get to pass throughs.

One thing I found out real quick - I'm out of practice. Haven't managed to burn thru anything I'm not supposed to yet, and the tin shields are a big help there. Just cut them as needed from some roof flashing and bend them over the sensitive bits.

For pins, I used clippings from capacitors that I've been collecting for just this job. I found out fast that it works better if I bend a little "J" hook in the first end. Basically just bend the wire against itself over some needlenose pliers, then bend it back out leaving a small loop that will stand proud of the solder pad. That helps to get the wire flat to the trace.

It's a four step process - for me anyway ...

- Lightly solder the bent wire into the hole, then use my handy dandy XActo scraper to push the wire tight to the trace. The "J" hook makes this easy to clear any ridge around the hole and get a nice tight fit. Also allows you to fine tune the wire so it matches the trace.

- Solder the wire to the scraped trace and top off the blob over the pass through point. Dragging the iron tip back from the blob over the wire gives a nice clean joint.

- Flip the board over, press the wire tight on that side and bend the wire to follow the scraped trace. Solder that same way the front was done. That's another point where that "J" loop on the front is handy - it adds a bit of spring tension to keep the wire tight and properly aligned to the traces on both sides when you reheat the joint.

- Double check the other side of the board. I had a couple joints bubble a bit. A quick touch up with the iron cleaned those up nice.

PS ... thanx everybody for talking me into the 40W Radio Shack desoldering tool. The 30 watter I'd been using wasn't quite hot enough to clean out the big blobs from the old pass through joints. Real easy to work with too.

About the arrow ... what the futterwaken is that?? It's soldered on the backside, but I see nothing for it to connect to on the front. One of those Sansui gotchas? As in ... well ... we thought we'd need one there but decided against it? Here's what it looks like from the other side after pinning.

If nothing else, it shows one of the scraped traces ready for a pin. Takes a light touch, so easy does it is the rule. I expect I'll just resolder the blob to nowhere before I pack it up. Still be interesting to find out if anyone else figured it out.

********

13 joints down - and depending on who you listen to - 37 or 39 more to go.

And another PS ... my cute lil holding jig for the board wasn't quite as handy as I thought it would be. It certainly had it's uses, but half the work was done propping the board up with a coffee can.

Last edited:

.jpg)

.jpg)

.jpg)

.jpg)