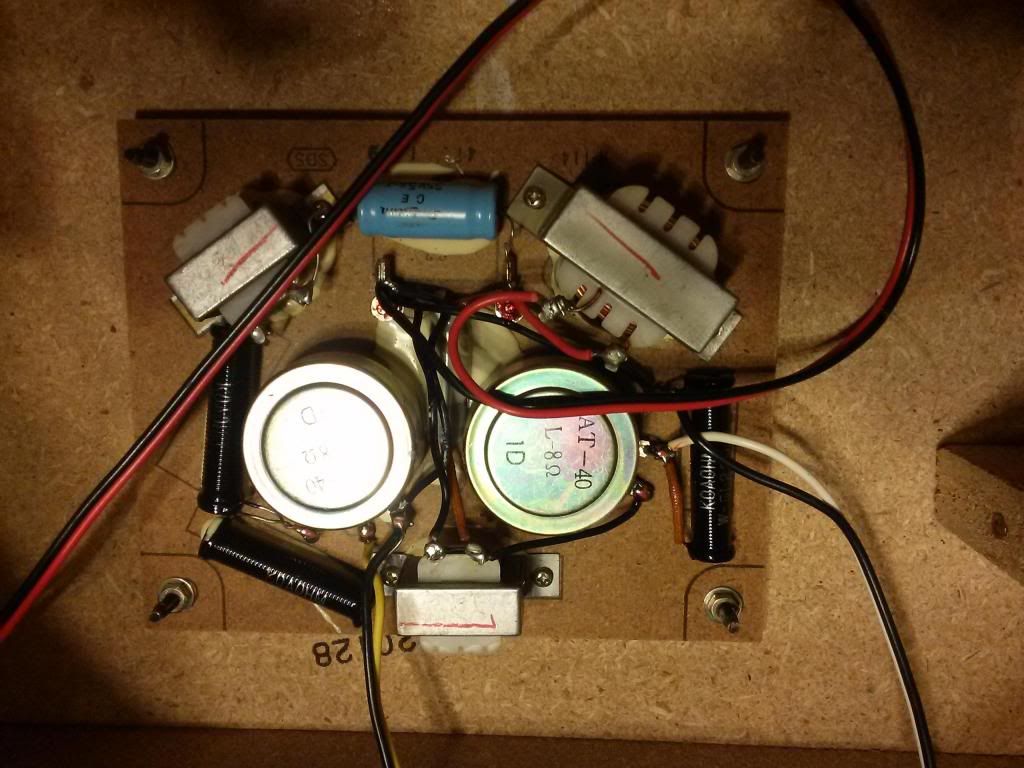

Anyone have a ball park range of what it might cost to get the crossovers in my AS-300's rebuilt? These are acoustic suspension speakers and it does not look very easy to open up. But their also older than my mother and things may be needing some maintenance.

Lately I've been noticing on my right speaker I'll get some static, or maybe it's clipping at slightly louder than normal volumes but really only on the high notes of the song. The left speaker will play fine, so I'm guessing it's something that's just an issue with that speaker.. or maybe the channel on my amp is going bad? At normal volumes it sounds fine tho.

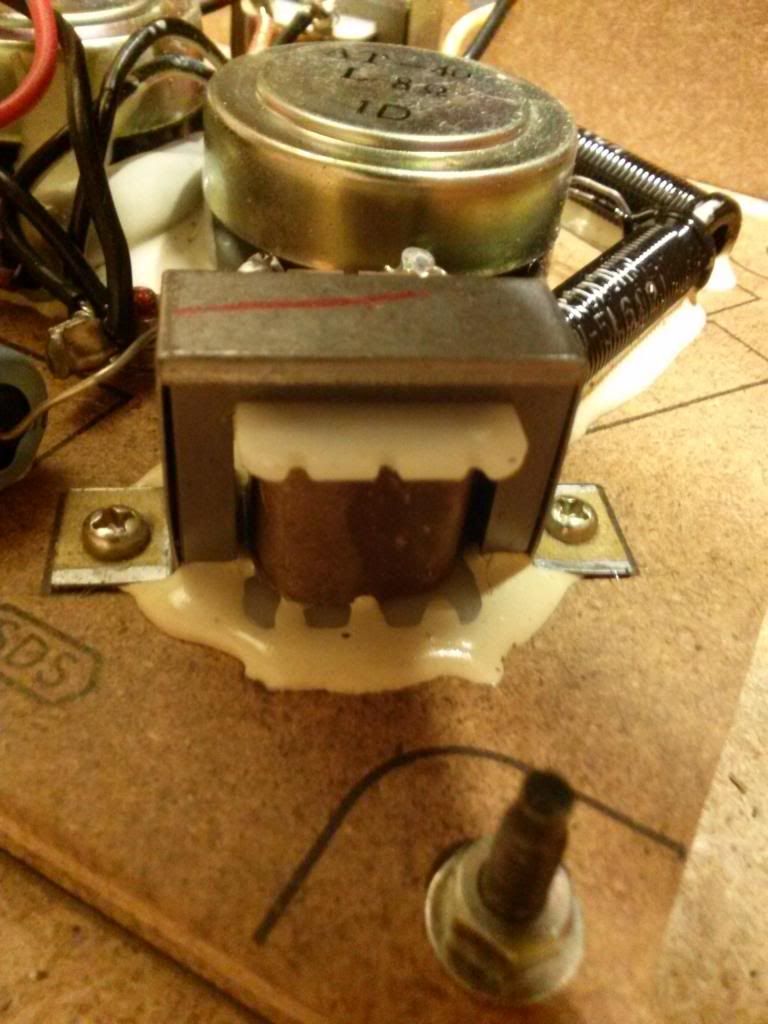

Whatever the issue is, I assume crossovers will need to be rebuilt eventually :/ . Is it worth doing it yourself? I have a soldering iron and minimal experience. Or better off taking it to a shop?

Lately I've been noticing on my right speaker I'll get some static, or maybe it's clipping at slightly louder than normal volumes but really only on the high notes of the song. The left speaker will play fine, so I'm guessing it's something that's just an issue with that speaker.. or maybe the channel on my amp is going bad? At normal volumes it sounds fine tho.

Whatever the issue is, I assume crossovers will need to be rebuilt eventually :/ . Is it worth doing it yourself? I have a soldering iron and minimal experience. Or better off taking it to a shop?