Thierry

Tape with a passion

Hi,

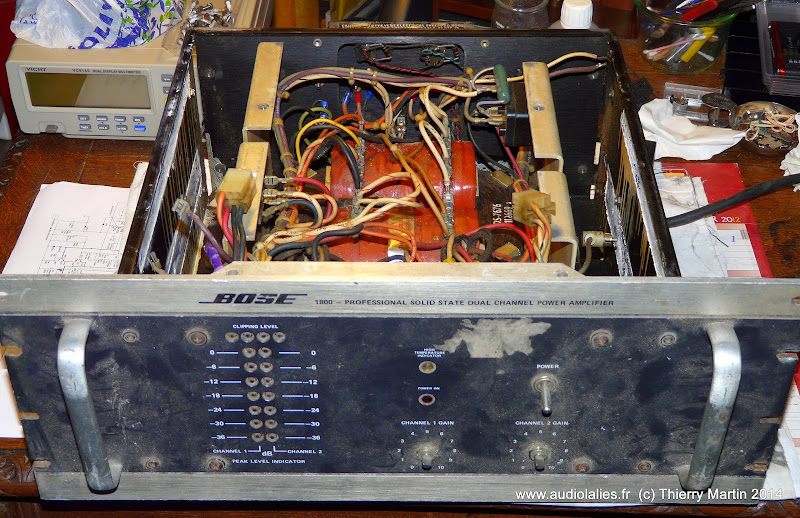

This one was rotting away in a basement and I just couldn't leave it there.

Got it for 20 euros (actually I gave twice this to the seller, I felt it was more honest) and stripped it down to the tiniest bit.

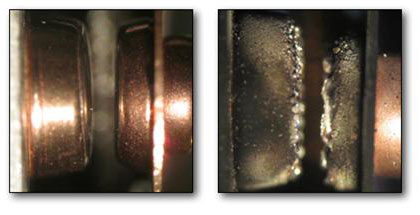

As you'll see it has been battered, pounded, abused and raped, but I guarantee that in the end it will look and sound better than new.

Watch this space https://picasaweb.google.com/109296933751482509949/Bose1800#slideshow/5987728582514331522 the saga continues !

Thierry

This one was rotting away in a basement and I just couldn't leave it there.

Got it for 20 euros (actually I gave twice this to the seller, I felt it was more honest) and stripped it down to the tiniest bit.

As you'll see it has been battered, pounded, abused and raped, but I guarantee that in the end it will look and sound better than new.

Watch this space https://picasaweb.google.com/109296933751482509949/Bose1800#slideshow/5987728582514331522 the saga continues !

Thierry